What Are the Differences Between Glass and Ceramics?

Glass and ceramics are commonly used materials in various applications, from daily necessities to advanced engineering products. Despite their similarities, glass and ceramics have different physical and chemical properties, which affect their applications and manufacturing processes. This article provides an in-depth analysis of glass and ceramics, including their definitions, properties, production methods, and applications.

Glass and ceramics are integral to many industries, including construction, electronics, healthcare, and engineering. Although they share some attributes, such as brittleness and non-metallic composition, they are not interchangeable. This paper analyzes the differences between glass and ceramics, offering insights into their structural properties, production methods, and specific applications. Understanding these differences is essential for professionals and researchers looking to select the most suitable material for various industrial applications.

Definitions and Key Characteristics

Glass

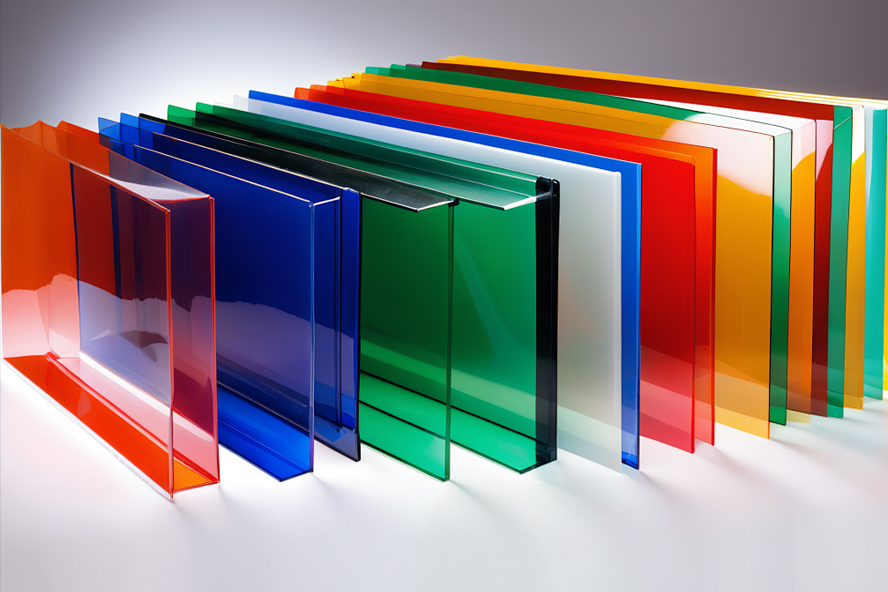

Glass is an amorphous, non-crystalline solid that forms

when a substance, typically silica (SiO₂), is rapidly cooled without undergoing crystallization. Its amorphous structure gives it unique optical clarity and transparency, which makes it ideal for applications like windows, lenses, and screens. Due to the disordered atomic arrangement, glass lacks the long-range order characteristic of crystalline materials, which impacts its physical properties, such as its tendency to break under stress rather than deform.

Ceramics

Ceramics, unlike glass, are polycrystalline materials with a highly ordered atomic structure. Produced from inorganic, non-metallic compounds (such as oxides, carbides, and nitrides), ceramics are known for their hardness, heat resistance, and mechanical strength. Ceramics can withstand high temperatures and are often used in applications requiring durability and resistance to wear.

Main characteristics of glass and ceramics

Glass | Ceramics |

Transparency | High Hardness and Strength |

Chemical Stability | Thermal Stability |

Brittleness | Electrical Insulation |

Glass Production

Glass is typically produced by melting raw materials (such as silica sand, soda ash, and limestone) at high temperatures (approximately 1,700°C) and then cooling the molten mixture quickly to avoid crystallization. This process, known as vitrification, results in an amorphous structure. Additional treatments, such as tempering and annealing, can further enhance the strength and durability of glass.

Ceramic Production

Ceramics are produced through a series of processes that include shaping, drying, and sintering. Raw ceramic powders are first mixed with binders and other additives to form a paste, which is then molded into the desired shape. The molded pieces are dried and then fired at high temperatures (often over 1,000°C) to achieve densification and enhance mechanical properties. Sintering fuses the ceramic particles together, forming a strong, solid piece with crystalline structures.

Applications of Glass and Ceramics

Glass | Ceramics |

Container | Electronic components |

Art and crafts | Aerospace |

Laboratory equipment | Medical devices |

Automotive industry | Automotive industry |

Optical components | Mechanical components |

Key Differences Between Glass and Ceramics

Property | Glass | Ceramics |

Atomic Structure | Amorphous, non-crystalline | Crystalline, ordered |

Transparency | Transparent | Usually opaque |

Thermal Resistance | Moderate | High |

Electrical Properties | Insulating or conductive (some types) | Primarily insulating |

Flexibility in Shaping | Easier to mold when molten | Shaping requires advanced methods |

Typical Applications | Windows, optical lenses, containers | Cutting tools, insulators, medical implants |

While glass and ceramics are both non-metallic materials with high durability, their structural differences make them suitable for different applications. Glass, with its transparency and amorphous structure, is best suited for optical and decorative uses, while ceramics, known for their hardness and thermal resistance, are essential in demanding engineering applications. Understanding these differences enables manufacturers and engineers to select the most appropriate material based on the specific requirements of their projects.

Jundro Ceramics excels in utilizing its technical expertise and advanced equipment to machine high-precision glass and ceramics, making it an ideal choice for various high-precision equipment Contact our experts, we are happy to provide you with services

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023