Silicon Nitride Ceramics

Silicon nitride (Si₃N₄) is a high-performance ceramic material characterized by exceptional properties, including high flexural strength, hardness, and remarkable stability at elevated temperatures, with a maximum temperature resistance exceeding 1200 °C. The silicon nitride ceramics exhibit a smooth surface and a low friction coefficient, rendering them particularly suitable for high-speed rotating or sliding applications. In demanding environments, their superior high-temperature resistance, corrosion resistance, and mechanical strength offer extensive opportunities for application, establishing silicon nitride as a preferred material across various industrial sectors.

Silicon Nitride Advantages

Si₃N₄ has high strength and hardness

Excellent high temperature resistance performance

Good thermal shock resistance

High antioxidant activity

Good corrosion resistance ability

Low friction coefficient and high wear resistance

Low density (about 3.2 g/cm ³)

High electrical insulation

Excellent biocompatibility

High fracture toughness

What can silicon nitride be used for

Ceramic bearings

Gas turbine blades

Turbocharger rotor

Semiconductor wafer transfer manipulator

Vacuum equipment components

Thermocouple protection tube

High temperature wear-resistant pump

Spark plug insulator

Piezoelectric sensor substrate

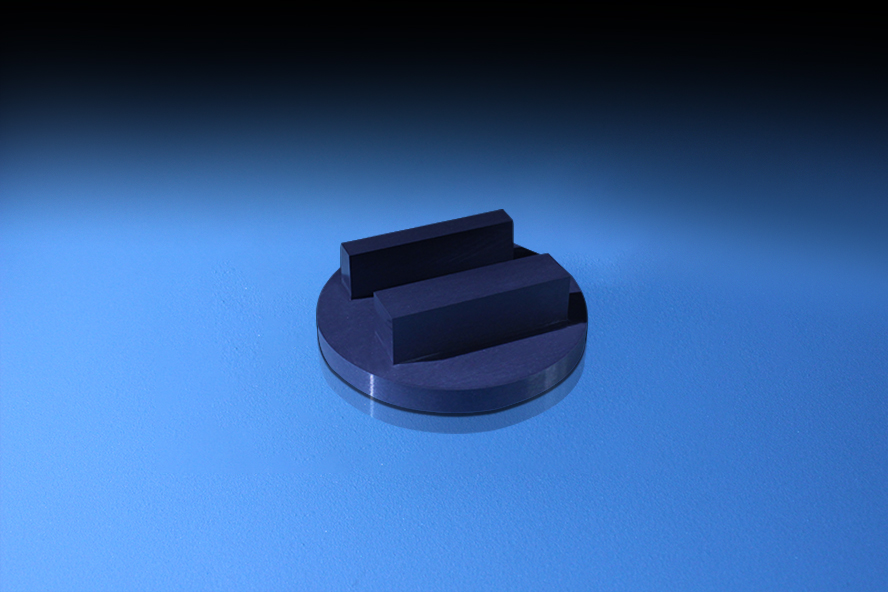

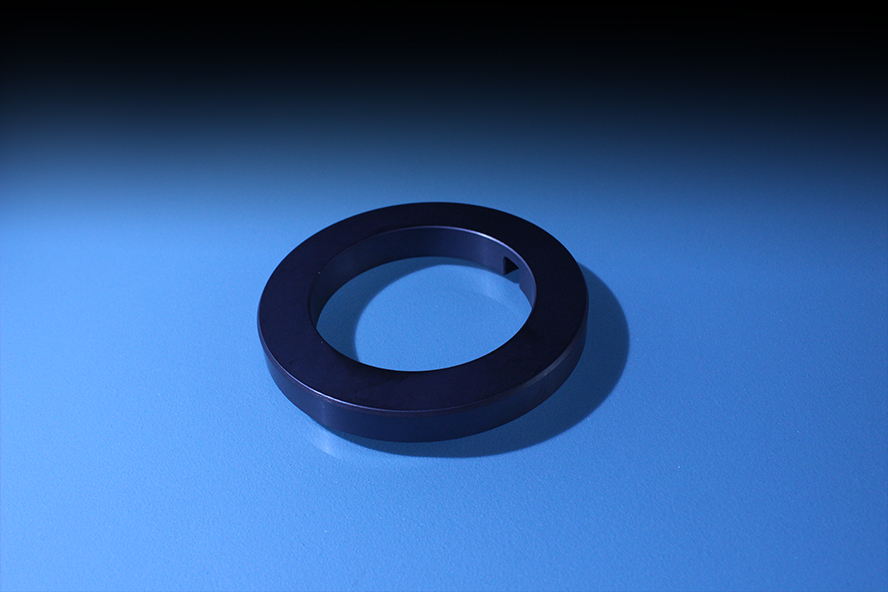

Products

Silicon Nitride Material Properties

Silicon nitride ceramic properties | Silicon nitride ceramic | ||

item | unit | Typical value | |

Physical property | |||

colour | black | ||

density | g/cm³ | 3.2 | |

Gas permeability | 0 | ||

hydroscopicity | <0.1 | ||

Mechanical property | |||

Monger hardness | Lv. | 9 | |

Rockwell hardness | HRA | 80 | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | 1400 | |

Bending strength (20 °C) | Mpa | 300 | |

Compressive strength (20 °C) | Mpa | 1000 | |

Modulus of elasticity | Gpa | 290 | |

Poisson's ratio (20 °C) | 0.25 | ||

Fracture toughness (20 °C) | MPa*1/2 | 5 MPa·m^0.5 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 25 | |

Thermal expansion | 10-6/℃ | 2.5 | |

Maximum service temperature | °C | 1400 | |

Electronic property | |||

Dielectric medium | KV/mm | 20 | |

Dielectric constant | Er | 4 | |

Dielectric loss Angle (1MHz) | 10^-4 | ||

Silicon Nitride Machining

Silicon nitride ceramic machining is a highly technical challenge, which presents considerable challenges due to its extremely high hardness and strength, especially its stability in high-temperature environments. Jundro Ceramics excels in working with strict tolerances and highly complex tasks. We have professional processing equipment, including 4-axis and 5-axis machining centers, providing precision machining, surface treatment, and quality testing. This enables us to produce silicon nitride ceramic components to the highest specifications

Jundro is a leading global supplier of silicon nitride ceramics, meeting all your technical ceramic manufacturing needs. We are committed to providing high-quality precision ceramic components that meet or exceed customer expectations for processing and production. If you would like to inquire about customized machining parts, please contact us, and one of our experts will be happy to assist you.