Zerodur

Zerodur is a microcrystalline glass-ceramic material, exhibiting a light yellow-brown appearance and characterized by an exceptionally low thermal expansion coefficient. This material is produced by Schott GmbH in Germany. Its thermal expansion can be considered negligible, even in the presence of substantial fluctuations in external temperature. Consequently, Zerodur is the material of choice for applications such as ring laser gyroscopes, astronomical telescopes, and specific laser components, demonstrating performance that is comparable to ultra-low expansion (ULE) glass. Jundro Ceramics is a global manufacturer of advanced materials, offering a diverse range of high-quality and complex products that significantly enhance performance for our customers' engineering requirements. Our extensive service offerings encompass material selection, precision machining, surface treatment, and quality inspection to ensure optimal results.

Zerodur Advantages

Can perform high-precision mechanical processing

Its average coefficient of thermal expansion is about 0 ± 0.007 · 10-6/K

Has strong stability to temperature changes

Zerodur has a uniform internal structure

Minimum deformation under load

Has good resistance to chemical substances such as acids and bases

Zerodur performs well in vacuum compatibility

Can provide transparency over a wide wavelength range

What can Zerodur be used for

Reflection mirror and bracket of laser gyroscope

X-ray mirror in synchrotron

Interferometer, optical table, length measurement system

Optical components of spectrometer

Laser interferometer

Planar wavefront sensor

Gravitational wave gravitational component

Optical satellite system

Astronomical telescope lenses (such as the main mirror of the Hubble Space Telescope)

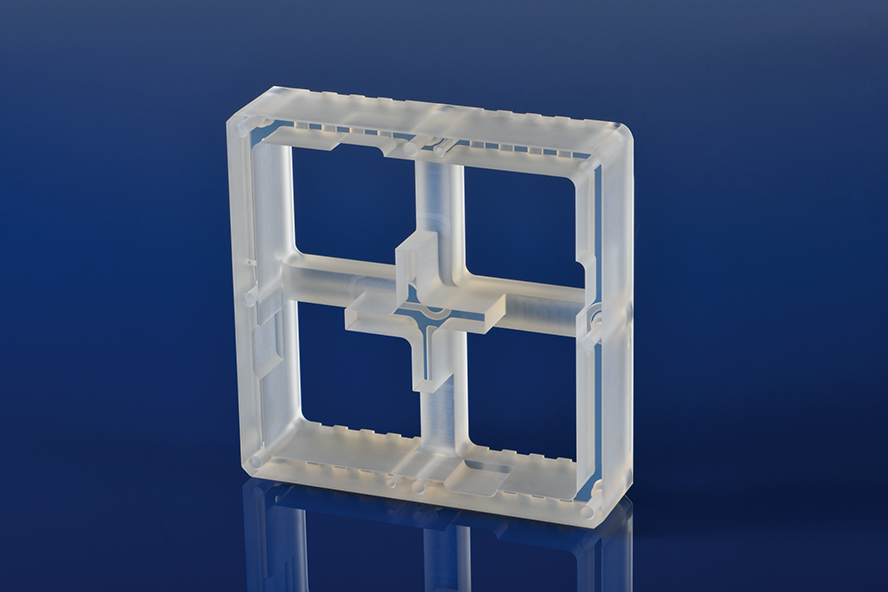

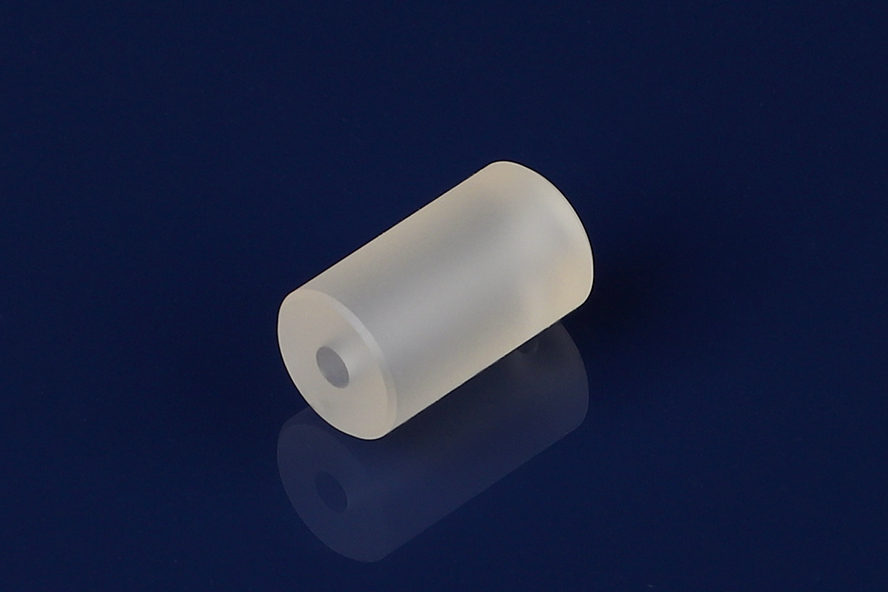

Products

Zerodur Material Properties

Performance of ZERODUR® | ZERODUR® | ||

item | unit | Typical value | |

Physical property | |||

colour | Translucent yellow | ||

density | g/cm³ | 3.26 | |

Gas permeability | - | ||

hydroscopicity | - | ||

Mechanical property | |||

Knoop hardness | HK | 620 | |

Rockwell hardness | HRA | - | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | - | |

Bending strength (20 °C) | Mpa | 690 | |

Compressive strength (20 °C) | Mpa | 2940 | |

Modulus of elasticity | Gpa | 470 | |

Poisson's ratio (20 °C) | 0.25 | ||

Fracture toughness (20 °C) | MPa*1/2 | 30 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 1.46 | |

Thermal expansion | 10-6/℃ | 0.72 | |

Maximum service temperature | °C | 600 | |

Electronic property | |||

Dielectric medium | KV/mm | - | |

Dielectric constant | Er | 1.4 | |

Dielectric loss Angle (1MHz) | - | ||

How to Machining Zerodur

When processing precision materials like Zerodur, it is necessary to master some processing techniques, select suitable cutting tools, control cutting speed, and avoid material damage caused by overheating. After processing, careful inspection is required to confirm that the surface of the part is free of cracks or broken edges. If necessary, further ultra precision polishing treatment is required.

Jundro Ceramics excels in utilizing years of processing experience to produce high-quality precision Zerodur components that meet or exceed customer pre orders, ensuring the needs of daily use and special performance. If you need to machine Zerodur components, please contact our experts