Silicon Carbide Ceramic

Silicon carbide (SiC) is a ceramic material that ranks second only to diamond in hardness. It exhibits excellent heat dissipation, stable chemical properties, and a low surface friction coefficient. Consequently, its wear resistance is outstanding across various contact surfaces. Silicon carbide ceramics can maintain stability over a wide temperature range, minimizing thermal deformation and enabling their application in fields such as electronics, automotive, aerospace, and industrial machinery.

Silicon Carbide Advantages

Hardness second only to diamond

SiC has extremely high temperature resistance

Excellent thermal conductivity

The thermal expansion coefficient of SiC is low (about 4.0 × 10 ⁻⁶/K)

Strong resistance to chemical corrosion

High fracture toughness and compressive strength

SiC material has good wear resistance

Excellent antioxidant properties

Can maintain high strength under both high and low temperature conditions

Low density, lighter than many metal materials

Silicon Carbide Uses

High temperature and high voltage power semiconductor devices

Mechanical wear-resistant seals

heat exchanger

Refractory lining

Gas turbine blades

SiC combustion nozzle

Optical reflector

High temperature sensor

SiC ceramic bearings

Power electronic heat dissipation substrate

High voltage transformer components

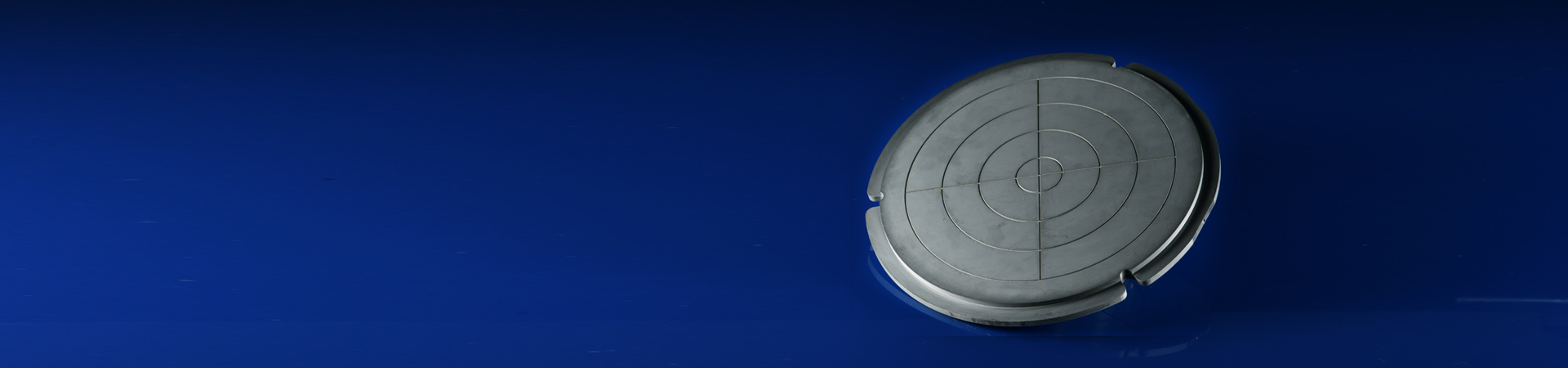

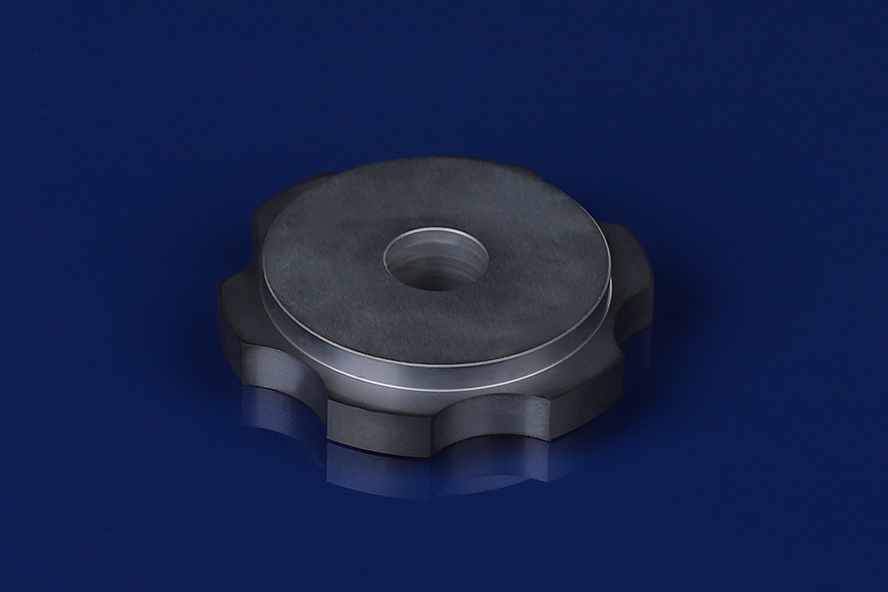

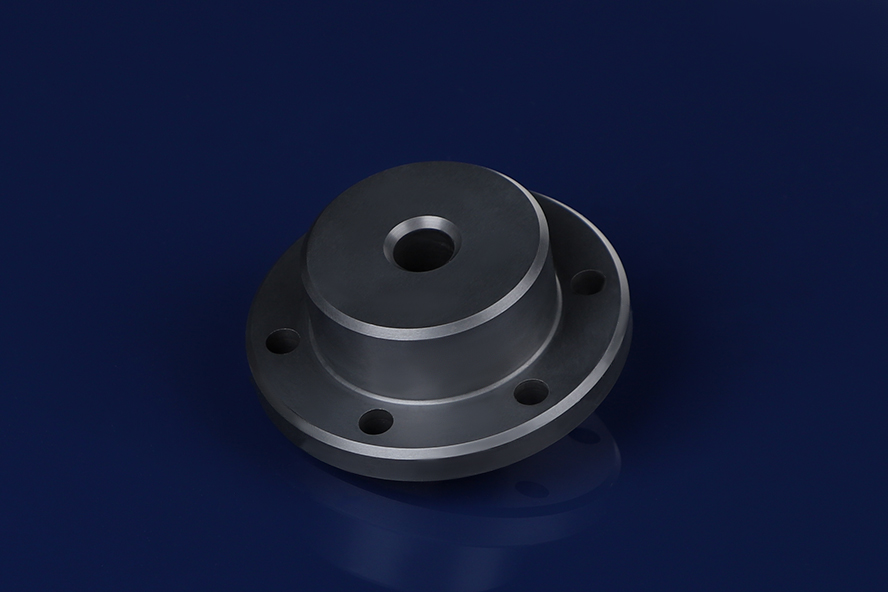

Products

-

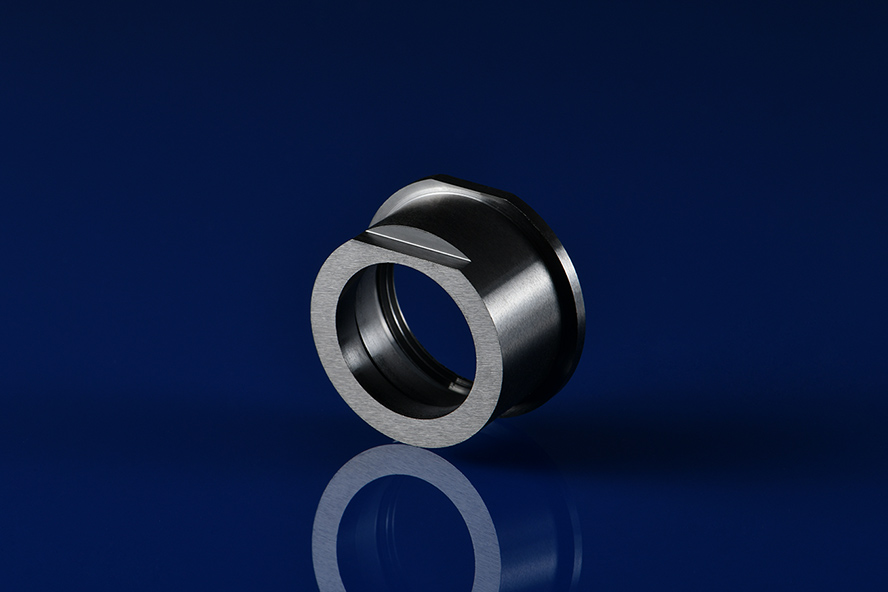

Silicon Carbide

Silicon Carbide -

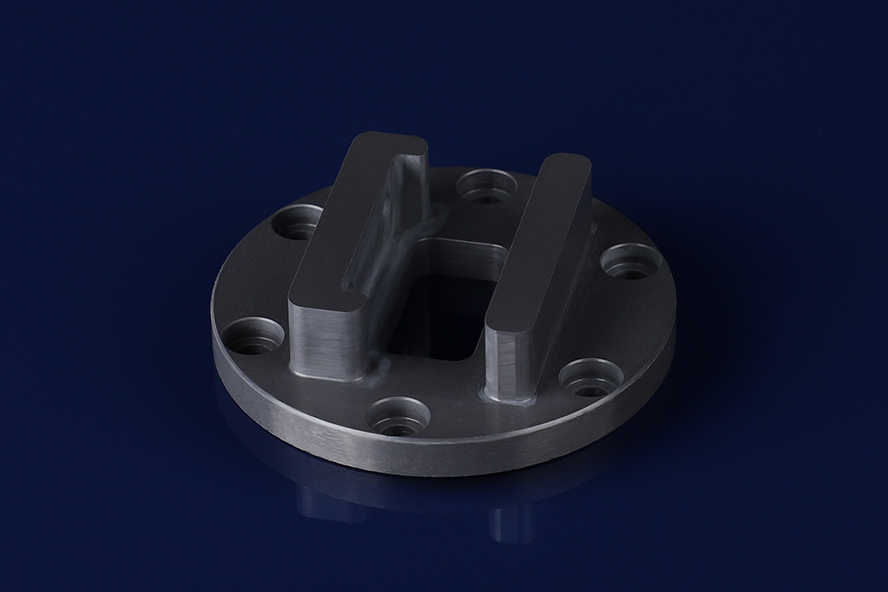

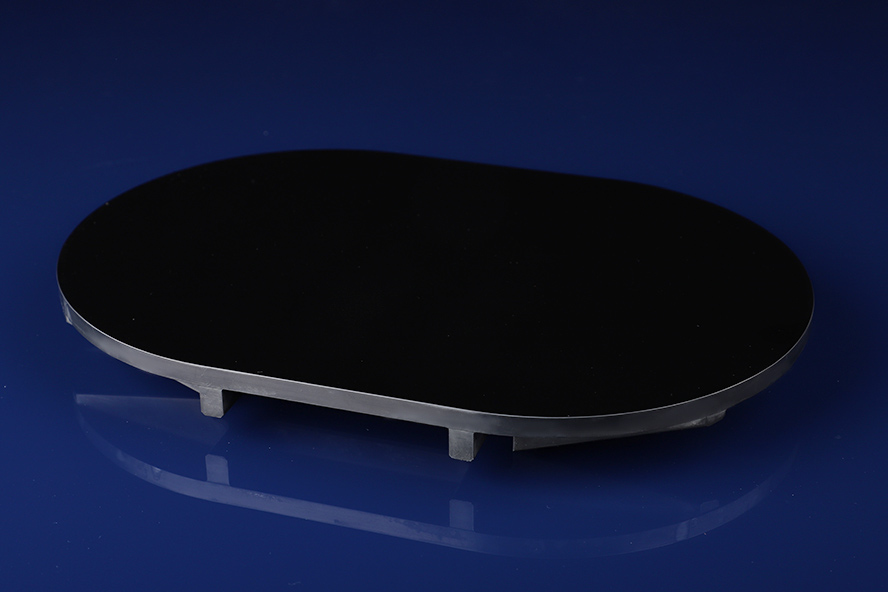

Silicon Carbide (SiC) Electrostatic Chuck

Silicon Carbide -

Silicon Carbide

Silicon Carbide -

Silicon Carbide

Silicon Carbide -

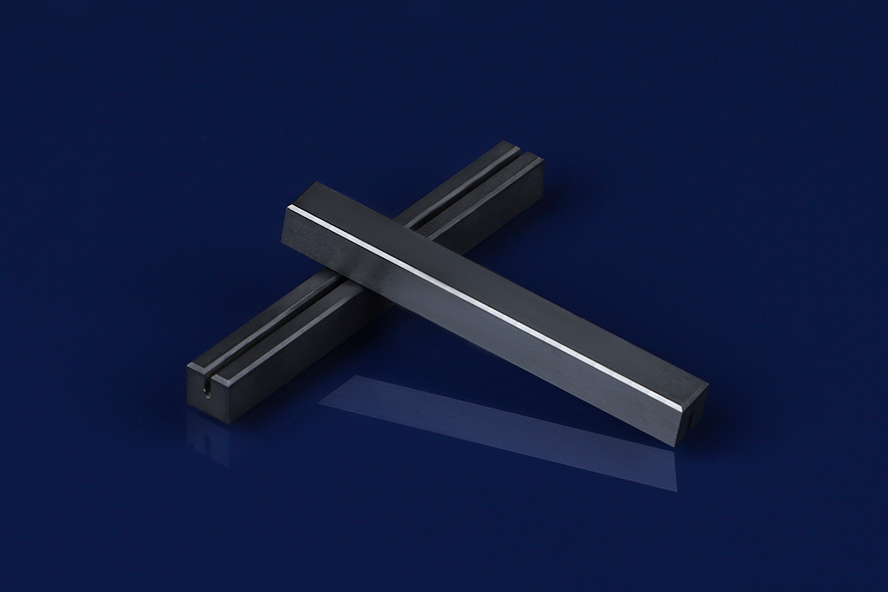

Silicon Carbide Ceramics Parts

Silicon Carbide -

Silicon Carbide Ceramics Machining

Silicon Carbide -

Silicon Carbide Optical Mirrors

Silicon Carbide -

Silicon Carbide Ceramic Guide Rail

Silicon Carbide -

Reaction Bonded Silicon Carbide

Silicon Carbide

Silicon Carbide Material Properties

Properties of silicon carbide | Silicon carbide ceramics | ||

item | unit | Typical value | |

Physical property | |||

colour | black. | ||

density | g/cm³ | 3.1 | |

Gas permeability | 1300 | ||

hydroscopicity | 0.10% | ||

Mechanical property | |||

Monger hardness | Lv. | 9 | |

Rockwell hardness | HRA | 90 | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | 500 | |

Bending strength (20 °C) | Mpa | 350 | |

Compressive strength (20 °C) | Mpa | 200 | |

Modulus of elasticity | Gpa | 300 | |

Poisson's ratio (20 °C) | 0.15 | ||

Fracture toughness (20 °C) | MPa*1/2 | 3 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 150 | |

Thermal expansion | 10-6/℃ | 3×10^-6 /°C | |

Maximum service temperature | °C | 1600 | |

Electronic property | |||

Dielectric medium | KV/mm | 5 | |

Dielectric constant | Er | 4 | |

Dielectric loss Angle (1MHz) | 0.001 | ||

Silicon Carbide Machining

Silicon carbide (SiC) is classified as a difficult to machine material due to its high hardness and brittleness, and conventional cutting, drilling, and milling processes are difficult to effectively treat it. In order to achieve precision machining of silicon carbide ceramics, specialized tools and techniques are usually used.

Jundro is a globally leading silicon carbide company with extensive experience in machining SiC. Through our customized processing services, it has become an ideal choice for various high-precision equipment. We provide high-quality and precise ceramic components for various industries such as semiconductor, machinery, chemical, aerospace, etc. If you would like to inquire about customized machining parts, please contact us and our experts will be happy to assist you.