Magnesium stabilized zirconia (ZrO2) ceramic processing service

Magnesium stabilized zirconia ceramics have brought revolutionary changes to the aerospace industry due to their unique high-temperature resistance, high wear resistance, corrosion resistance, lightweight and high strength, and biocompatibility. With the advancement of technology and the deepening of applications, we can foresee that this material will play a more important role in future aerospace spacecraft

Products

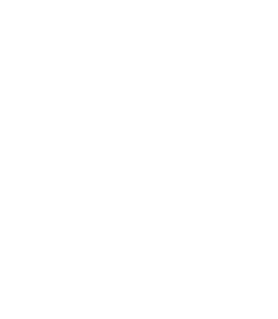

-

Magnesium stabilized zirconia ceramic processing services

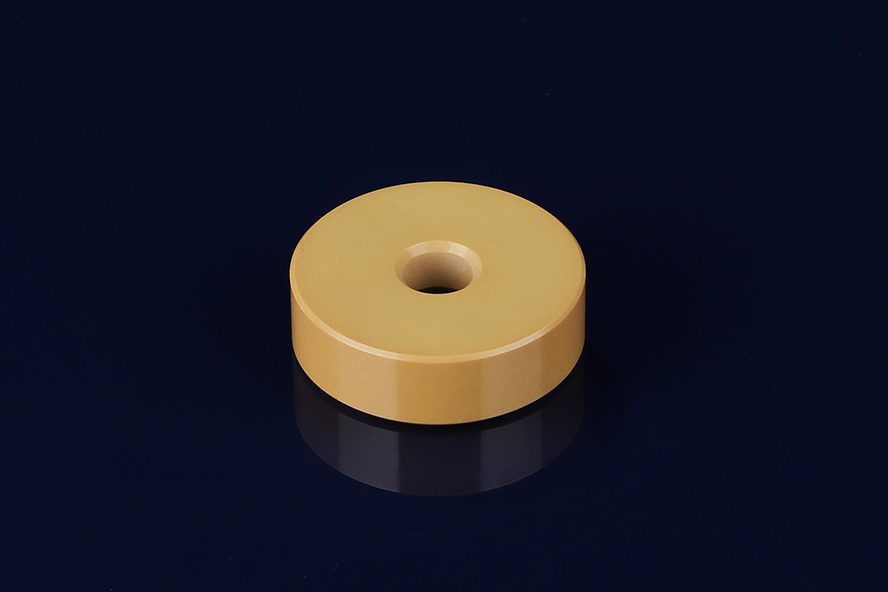

Magnesium stabilized zirconia -

Magnesium stabilized zirconia parts

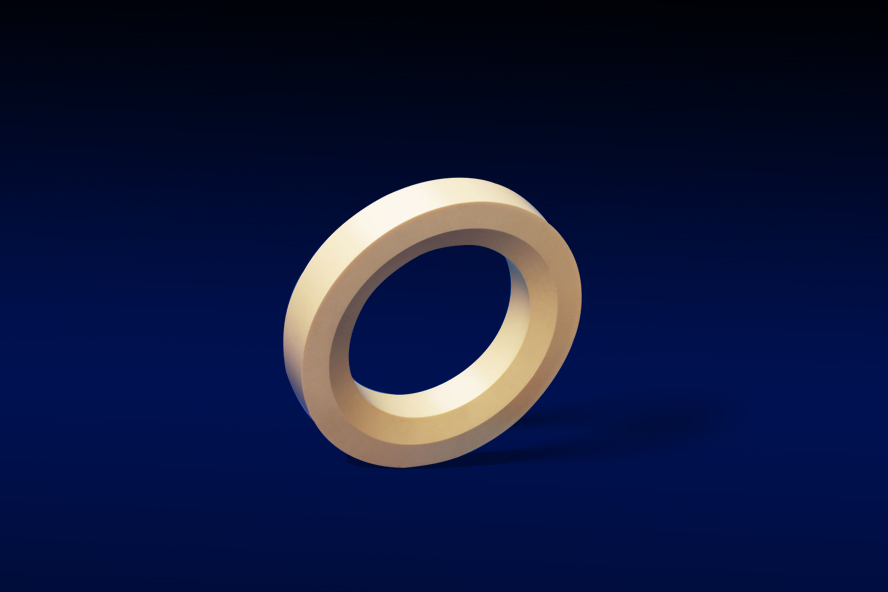

Magnesium stabilized zirconia -

Magnesium zirconia ceramic ring

Magnesium stabilized zirconia