Yttria Stabilized Zirconia

Yttria stabilized zirconia (YSZ) is a high-performance ceramic known for its remarkable strength, toughness, and exceptional thermal stability. This advanced material is widely utilized in demanding applications, including thermal barrier coatings, solid oxide fuel cells (SOFC), and dental prosthetics. YSZ's unique properties, such as low thermal conductivity and excellent wear resistance, make it ideal for environments subjected to high temperatures and harsh conditions. Its ability to maintain structural integrity under extreme stress ensures long-lasting performance in aerospace, automotive, and energy sectors. Explore how yttria stabilized zirconia can enhance your projects with superior durability and reliability.

Products

-

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

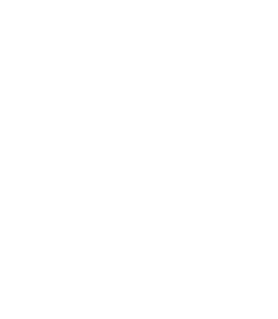

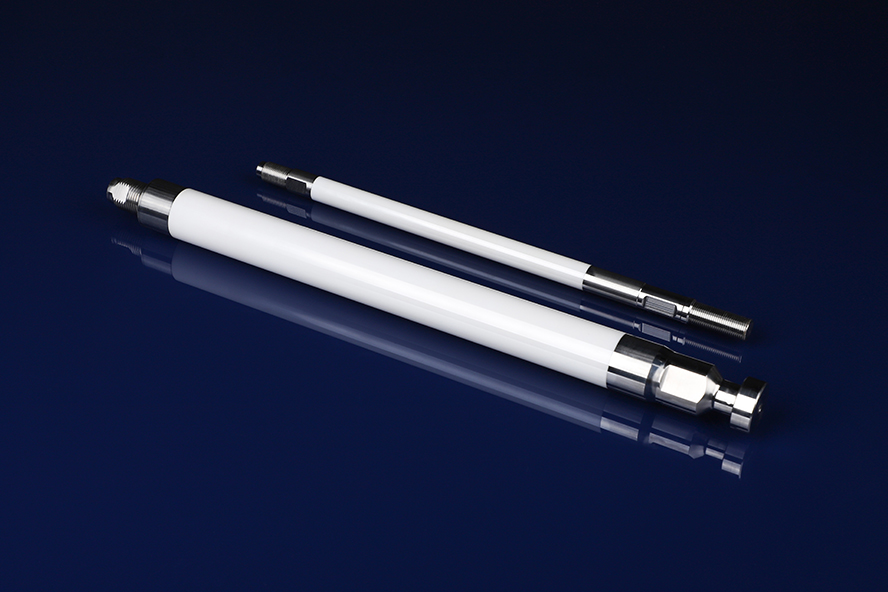

Zirconia ceramic plunger component

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

Yttrium stabilized zirconia

Yttrium stabilized zirconia -

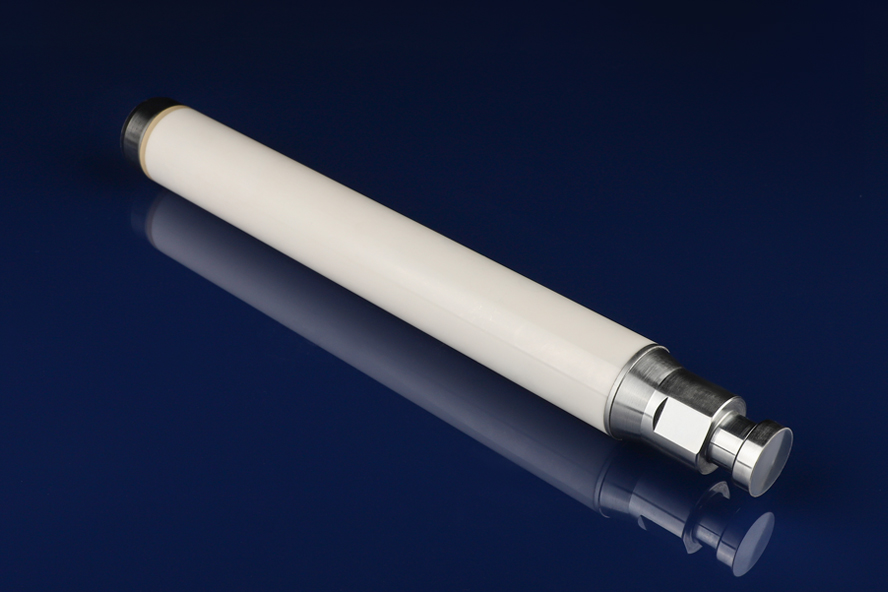

Highly wear-resistant zirconia ceramics

Yttrium stabilized zirconia

Zirconia ceramic properties | Zirconia ceramic | ||

item | unit | Typical value | |

Physical property | |||

colour | white | ||

density | g/cm³ | 1 | |

Gas permeability | 0 | ||

hydroscopicity | 0.1 | ||

Mechanical property | |||

Monger hardness | Lv. | 7 | |

Rockwell hardness | HRA | 80 | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | 900 | |

Bending strength (20 °C) | Mpa | 700 | |

Compressive strength (20 °C) | Mpa | 2000 | |

Modulus of elasticity | Gpa | 150 | |

Poisson's ratio (20 °C) | 0.25 | ||

Fracture toughness (20 °C) | MPa*1/2 | 10 MPa·m^0.5 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 3 | |

Thermal expansion | 10-6/℃ | 10 | |

Maximum service temperature | °C | 2000 | |

Electronic property | |||

Dielectric medium | KV/mm | 20 | |

Dielectric constant | Er | 10 | |

Dielectric loss Angle (1MHz) | 10^-4 | ||