Shapal-HI-M

Shapal HI-M is a high-performance machinable aluminum nitride ceramic material that has shown outstanding performance in industries such as electronics, semiconductors, electronic components, and engineering. It has unique high thermal conductivity, electrical insulation, high strength, and good chemical stability. Its unique microstructure gives it excellent machinability, allowing for precision machining using conventional metal processing tools, greatly reducing processing time and costs. Jundro Ceramics is a reliable supplier of Shapal HI-M, achieving fast and precise machining. The ideal choice for engineering projects.

Shapal-HI-M Advantages

Has a low coefficient of thermal expansion

Excellent electrical insulator

Easy to process into complex shapes

Good high thermal shock resistance

High mechanical strength and hardness

Can withstand various acids and bases

Performed well in a vacuum environment

High thermal conductivity, approximately 90-100 W/m ·

What can Shapal HI-M be used for

High precision insulation substrate

Thermal isolation materials in vacuum environment

Plasma etching equipment

High temperature sensor

X-ray and electron beam equipment

High precision machinery

Ion beam processing equipment

Insulation components for high-frequency equipment

Insulation components in vacuum systems

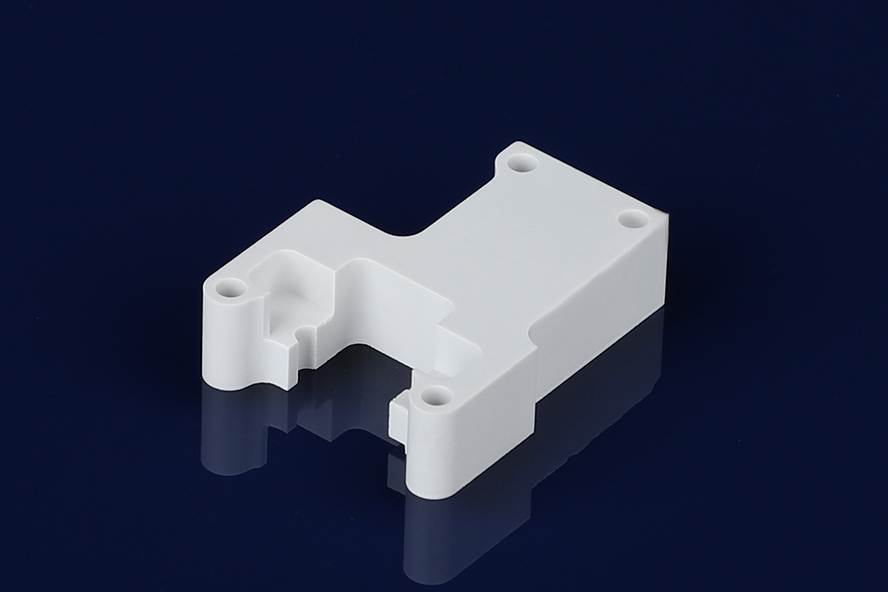

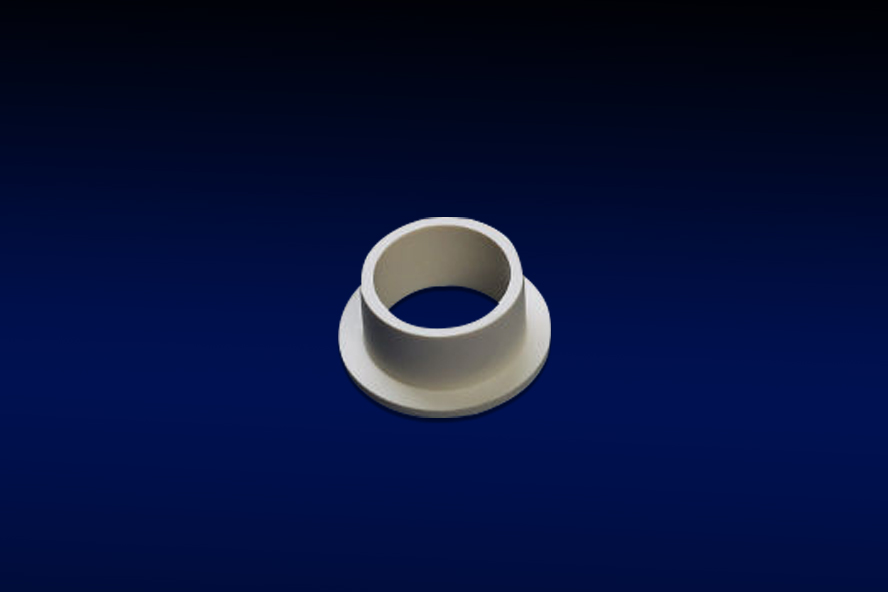

Products

-

Shapal-HI-M

Shapal-HI-M -

Shapal-HI-M

Shapal-HI-M -

Machinable Aluminum Nitride Ceramic

Shapal-HI-M

Shapal Hi M Material Properties

Material Properties | Unit | Shapal Hi M |

Density | g/cm³ | 2.9 |

Vickers hardness | HV | 250 |

Bending strength | MPa | 350 |

Compressive strength | MPa | 1100 |

Elastic modulus | GPa | 290 |

Toughness | MPa·m¹/² | 2.4 |

Poisson's ratio | 0.31 | |

Young’s Modulus | GPa | 176 |

Thermal Properties | Unit | Shapal Hi M |

Thermal Conductivity @ -100°C | W/mK | 100 |

Thermal Conductivity @ 25°C | W/mK | 92 |

Thermal Conductivity @ 500°C | W/mK | 55 |

Thermal Conductivity @ 1000°C | W/mK | 35 |

Thermal Shock Resistance ΔT | °C | 400 |

CTE1 25°C —400°C | 10-6/K | 4.8 |

CTE1 25°C —600°C | 10-6/K | 4.9 |

Maximum Temperature (Inert) 2 | °C | 1900 |

Electrical Properties | Unit | Shapal Hi M |

Dielectric constant | 1 MHz | 8.6 |

Breakdown strength | kV/mm | 14 |

Dielectric loss | 1 MHz | 0.001 |

Volume resistivity @ 25 ° C | Ω·cm | 10*1015 |

Volume resistivity @ 500 ° C | Ω·cm | 3.2*1010 |

Volume resistivity @ 1000 ° C | Ω·cm | 4.6*105 |

Note: This value is for reference only and may vary slightly depending on the batch conditions.