95-99.8% Alumina Ceramic

Aluminum oxide ceramics are the most widely used technical ceramics, utilizing their excellent properties such as wear resistance and high hardness, electrical insulation, chemical corrosion resistance, high strength and hardness, with a melting point of up to 2050 ° C. They can maintain excellent performance in high temperature environments. The commonly used aluminum oxide ceramics are classified according to purity: 90% -99.9%. Among them, aluminum oxide with a purity below 97% is more suitable for surface metallization treatment due to its large grain structure, and can achieve processes such as brazing. The surface of high-purity alumina ceramics usually presents a finer texture and can be polished to a roughness of less than Ra0.02. Alumina with a purity higher than 99.8% is widely used in industries such as semiconductors and healthcare. Junjie has many years of experience in processing alumina ceramics and can provide alumina ceramic processing services that can maintain stability and reliability in special scenarios such as mechanical manufacturing, chemical, electronic, and electrical industries

Alumina Ceramics Advantages

Has good biocompatibility

Good insulation properties

Chemical corrosion resistance

Excellent high-temperature stability

Mohs hardness up to 9

Capable of withstanding large mechanical loads

Low thermal expansion coefficient

Excellent thermal conductivity

Excellent antioxidant performance

Alumina Ceramics Uses

Electronic packaging substrate

Microwave Window

Equipment lining

High voltage insulator

Artificial joints, dental implants

Igniter insulator

Valve seals, chemical pumps

High temperature support structure

Laser optical components

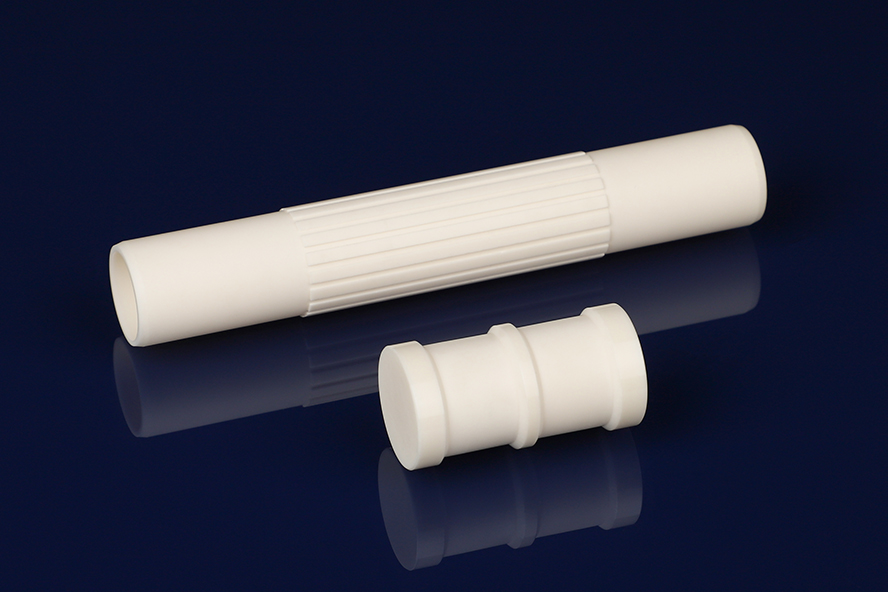

Sealing rings in mechanical equipment

Products

-

95-99.8%Alumina (Al₂O₃)

95-99.8%Alumina (Al₂O₃) -

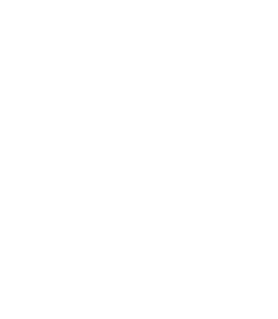

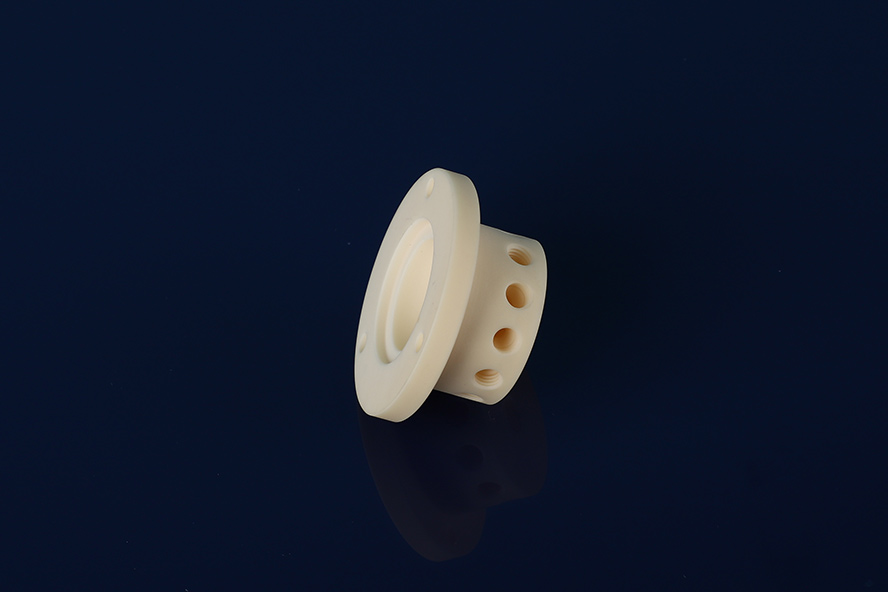

Aluminum oxide ceramic structural components

95-99.8%Alumina (Al₂O₃) -

High purity alumina ceramic structural components

95-99.8%Alumina (Al₂O₃) -

Aluminum oxide ceramic structural components

95-99.8%Alumina (Al₂O₃) -

95-99.8%Alumina (Al₂O₃)

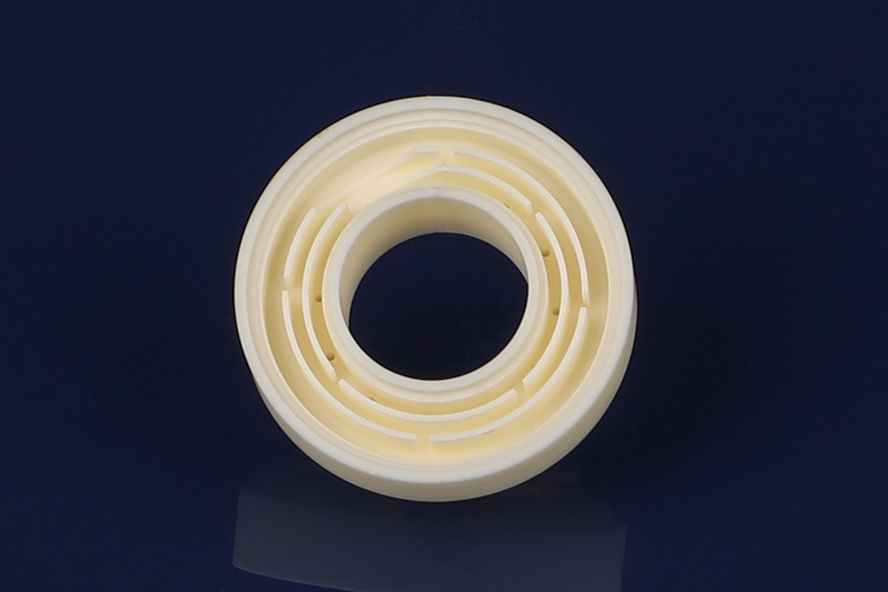

95-99.8%Alumina (Al₂O₃) -

95-99.8%Alumina (Al₂O₃)

95-99.8%Alumina (Al₂O₃) -

Ceramic Parts Of Semiconductor

95-99.8%Alumina (Al₂O₃) -

95-99.8%Alumina (Al₂O₃)

95-99.8%Alumina (Al₂O₃) -

Aluminum oxide ceramic valve core

95-99.8%Alumina (Al₂O₃) -

95-99.8%Alumina (Al₂O₃)

95-99.8%Alumina (Al₂O₃)

Alumina Ceramics Material Properties

Alumina ceramic properties | Alumina ceramic | ||

item | unit | Typical value | |

Physical property | |||

colour | yellowish | ||

density | g/cm³ | 3.9 | |

Gas permeability | 0 | ||

hydroscopicity | 0 | ||

Mechanical property | |||

Monger hardness | Lv. | 9 | |

Rockwell hardness | HRA | - | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | 17.2GPa | |

Bending strength (20 °C) | Mpa | 350 | |

Compressive strength (20 °C) | Mpa | 2500Mpa | |

Modulus of elasticity | Gpa | 380 | |

Poisson's ratio (20 °C) | 0.23 | ||

Fracture toughness (20 °C) | MPa*1/2 | 3.5MPam1/2 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 20 | |

Thermal expansion | 10-6/℃ | 15 | |

Maximum service temperature | °C | 1600 | |

Electronic property | |||

Dielectric medium | KV/mm | 20 | |

Dielectric constant | Er | 8 | |

Dielectric loss Angle (1MHz) | 10^-4 | ||

Aluminum Ceramics Machining

Jundro ceramics can achieve complex three-dimensional shapes and high-precision processing of alumina ceramic parts. Through the control of the CNC system, various complex geometric structures such as grooves, holes, and surfaces can be accurately machined. Jundro offers customized alumina ceramics in multiple sizes, purities, shapes, and a range of surface finishes to perfectly fit your equipment and specific needs. If you want to customize processed parts, please contact us.