Processing of boron carbide ceramics

Boron carbide ceramics are ceramic materials composed of carbon and boron elements. It has many unique characteristics. Boron carbide ceramics have excellent toughness, can withstand high-strength impact and tensile forces, and can maintain its structural integrity and mechanical properties in extreme high temperature environments. Its melting point is above 3000 degrees Celsius, making it widely used in various fields. Jundro provides you with unique processing services for boron carbide (B4C) ceramics

Products

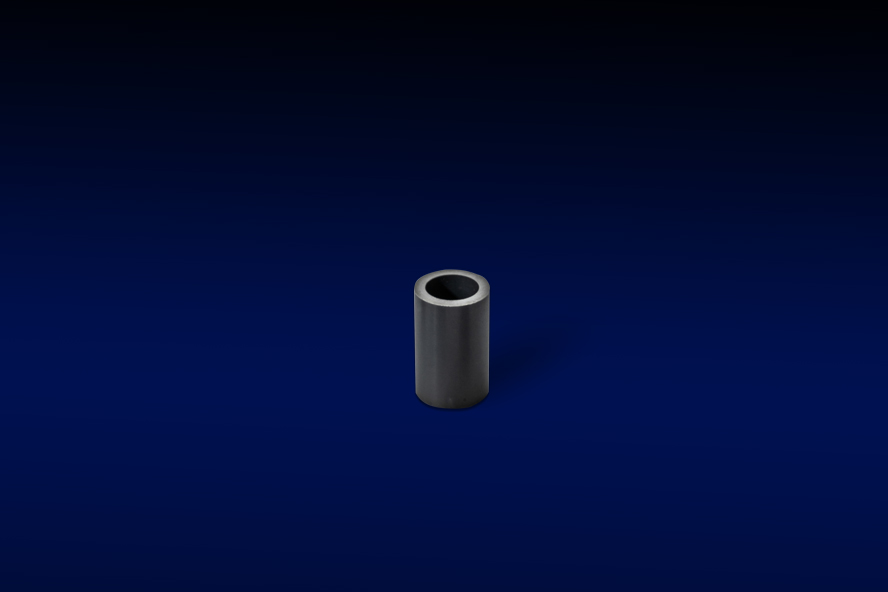

-

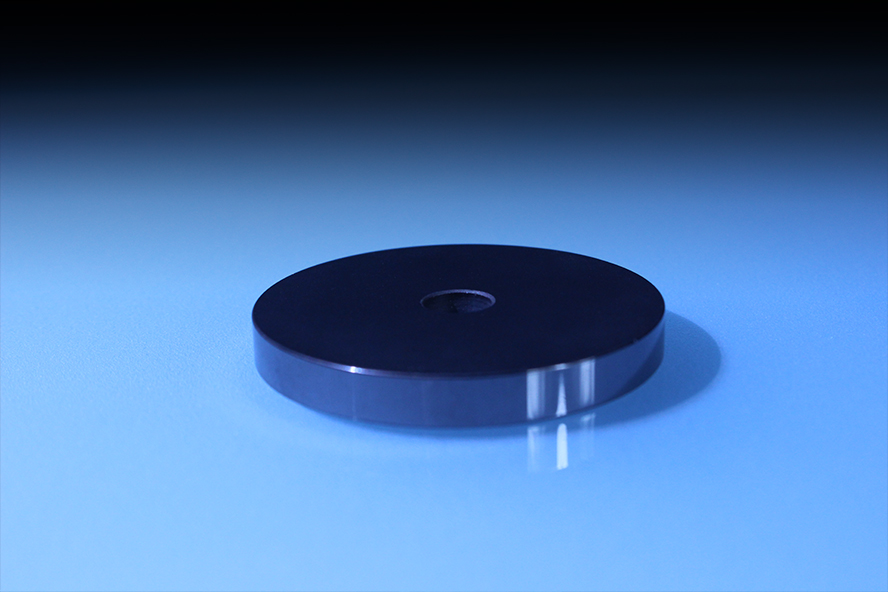

Boron Carbide

Boron Carbide -

Excellent performance boron carbide ceramics

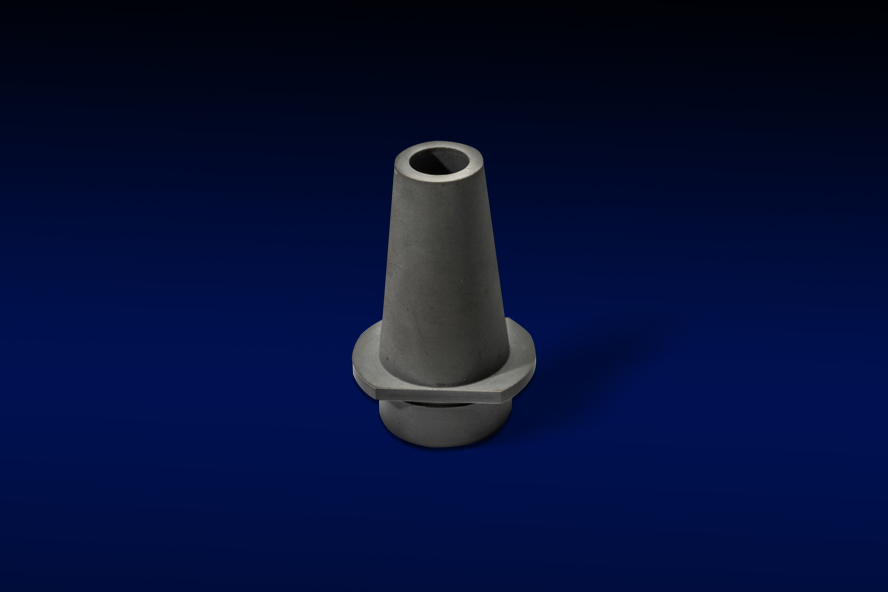

Boron Carbide -

Boron carbide ceramic structural components

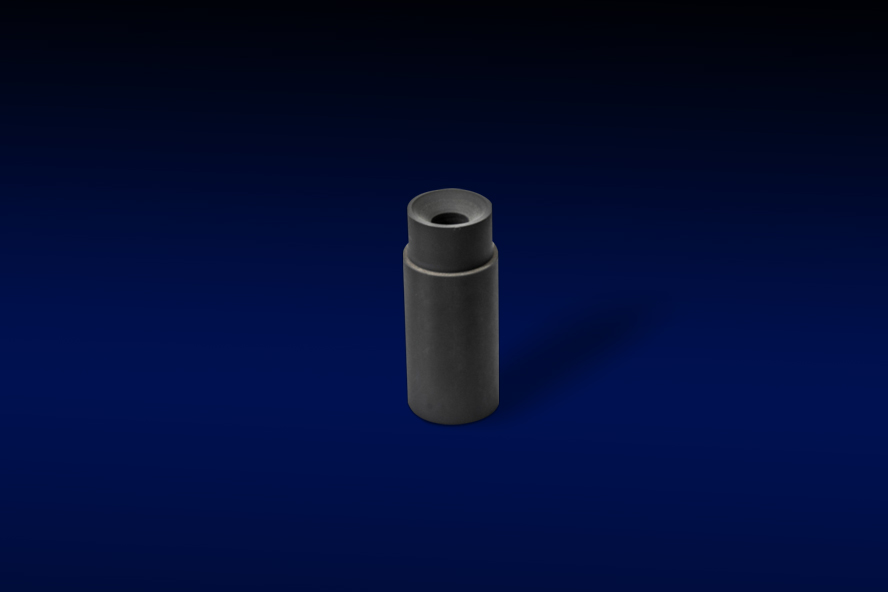

Boron Carbide -

High precision boron carbide ceramics

Boron Carbide

Boron carbide ceramic properties | Boron carbide ceramics | ||

item | unit | Typical value | |

Physical property | |||

colour | black | ||

density | g/cm³ | 2.52 | |

Gas permeability | 0 | ||

hydroscopicity | <0.1 | ||

Mechanical property | |||

Monger hardness | Lv. | 9.5 | |

Rockwell hardness | HRA | 80 | |

Vickers Hardness (Hv50) | Gpa(kg/mm) | 2800 | |

Bending strength (20 °C) | Mpa | 400 | |

Compressive strength (20 °C) | Mpa | 3500 | |

Modulus of elasticity | Gpa | 450 | |

Poisson's ratio (20 °C) | 0.22 | ||

Fracture toughness (20 °C) | MPa*1/2 | 3 MPa·m^0.5 | |

Thermal performance | |||

Thermal conductivity (20 °C)-400°C | W/(m·K) | 25 | |

Thermal expansion | 10-6/℃ | 2.7 | |

Maximum service temperature | °C | 2000 | |

Electronic property | |||

Dielectric medium | KV/mm | 15 | |

Dielectric constant | Er | 4 | |

Dielectric loss Angle (1MHz) | 10^-4 | ||