Sapphire Glass

Sapphire glass, also known as synthetic sapphire or aluminum oxide (Al₂O₃), is a highly durable high-performance material known for its outstanding performance. It exhibits strong acid and alkali resistance, as well as excellent corrosion resistance, making it an ideal choice for harsh environments. The melting point of sapphire glass is about 2040 ° C, which is very suitable for high-temperature applications. Its low thermal expansion coefficient ensures dimensional stability, even in environments with temperature fluctuations.Jundro Ceramics provides top-notch sapphire processing services, tailored to your specific needs for precision and quality.

Sapphire Glass Advantages

Excellent optical transparency

Excellent high temperature resistance

Excellent tolerance to most chemicals

High compressive strength and impact resistance

Excellent scratch resistance

Good thermal conductivity

Good electrical insulation

Has good tolerance to radiation

Sapphire Glass Uses

Watch surface

Optical Window

Bulletproof glass

Aerospace Window

Medical equipment window

Substrate material

Military optical instruments

Pressure sensor

Chemical observation window

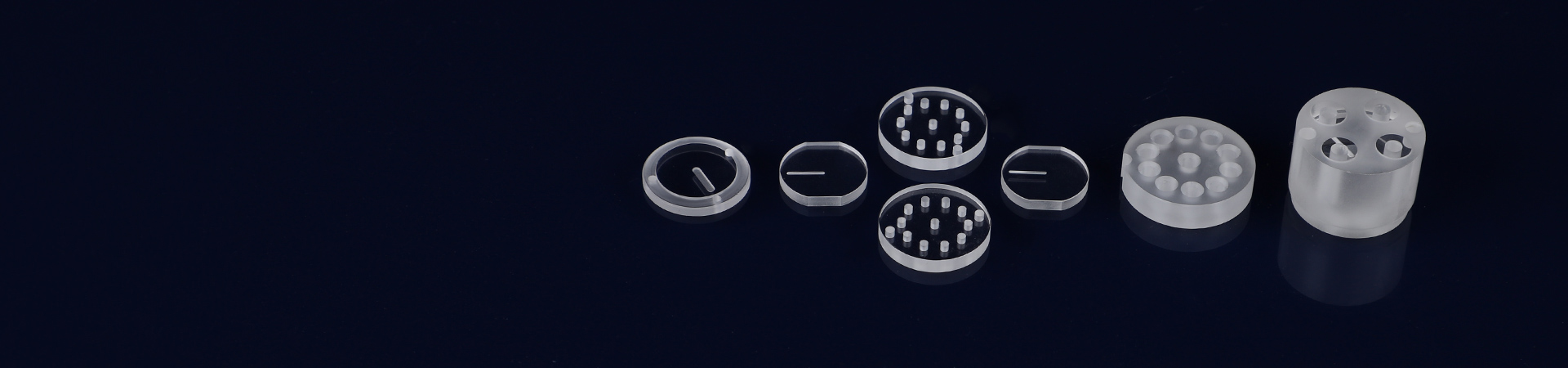

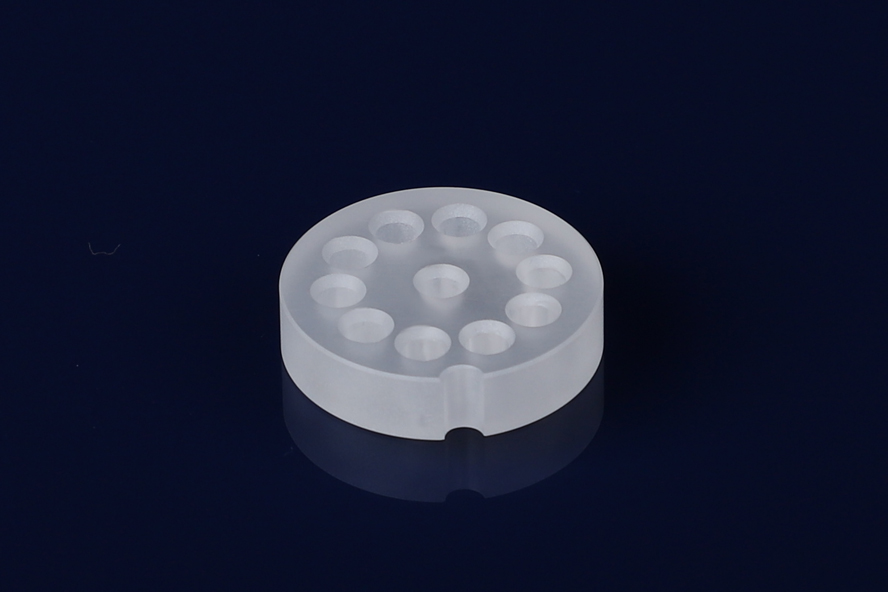

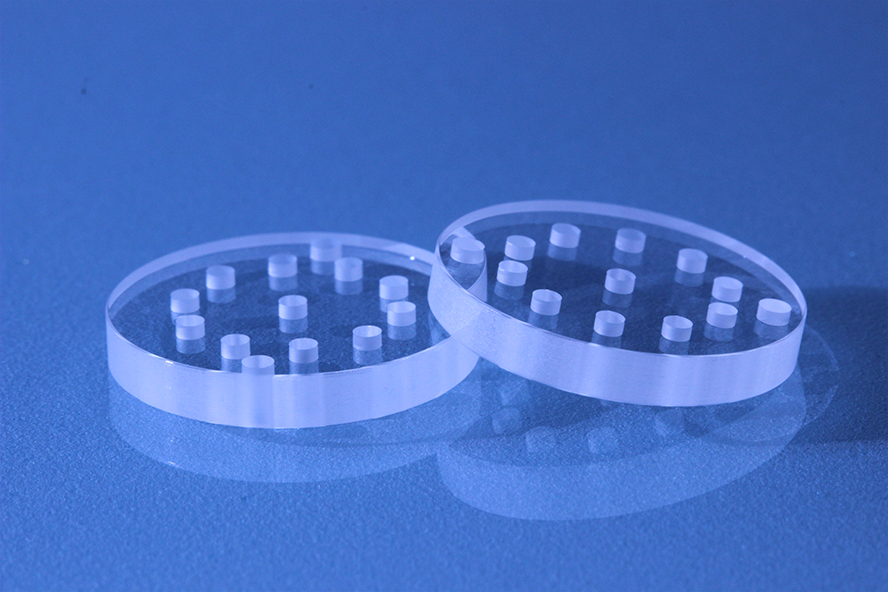

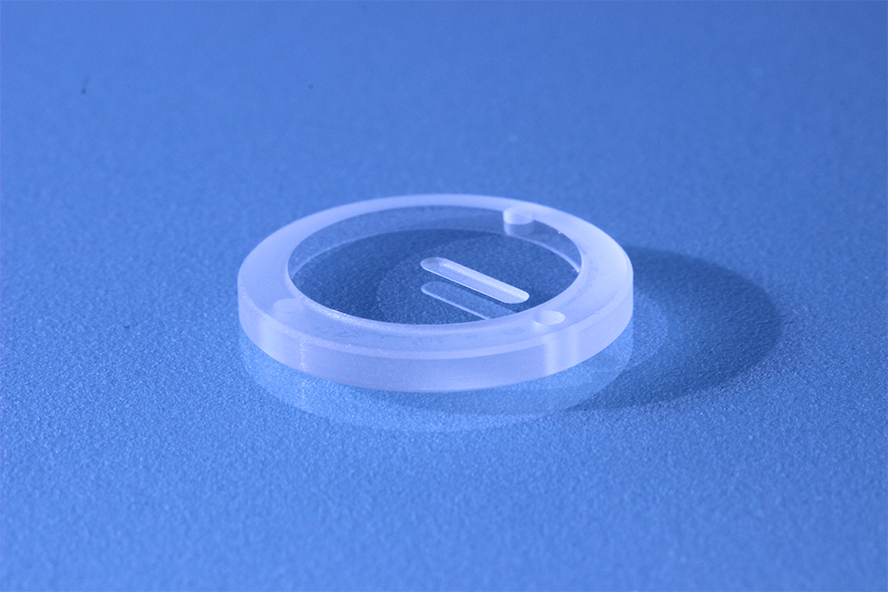

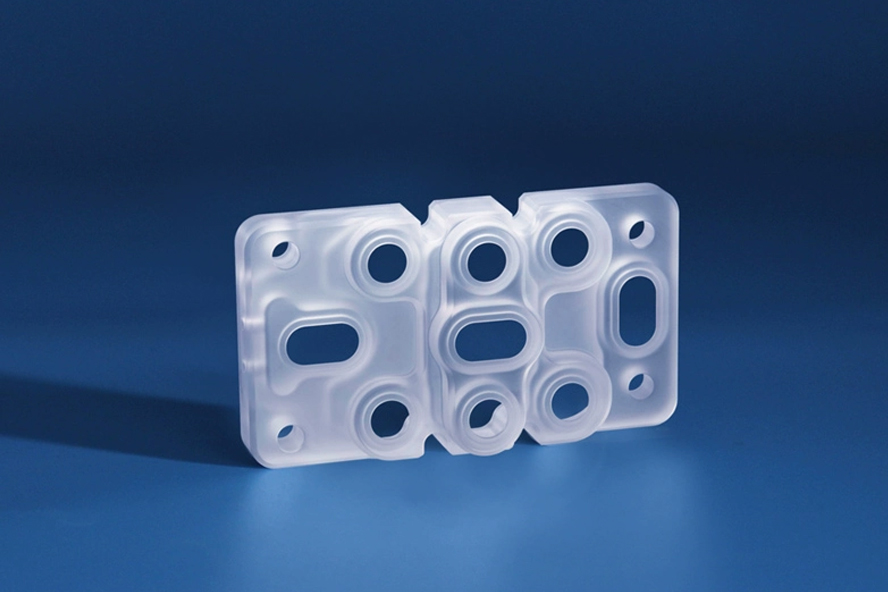

Products

Sapphire Glass Material Properties

| item | Sapphire glass |

| colour | colourless |

| density | 3.97 |

| Compressive strength | 2940MPa |

| Fracture toughnes | 5 |

| Hardness (Hv50) | 22.5 |

| Young's modulus | 470Gpa |

| Poisson's ratio | 0.18 |

| Thermal conductivity @25℃ | 42 |

| Dielectric constant @25℃ | 9 |

Sapphire Glass Machining

Sapphire processing is quite complex and requires specialized equipment and technology, requiring experienced technicians to precisely control the processing

Jundro Ceramics can provide sapphire glass processing services that can maintain stability and reliability in special scenarios according to your unique needs

If you need, you can contact our experts for consultation