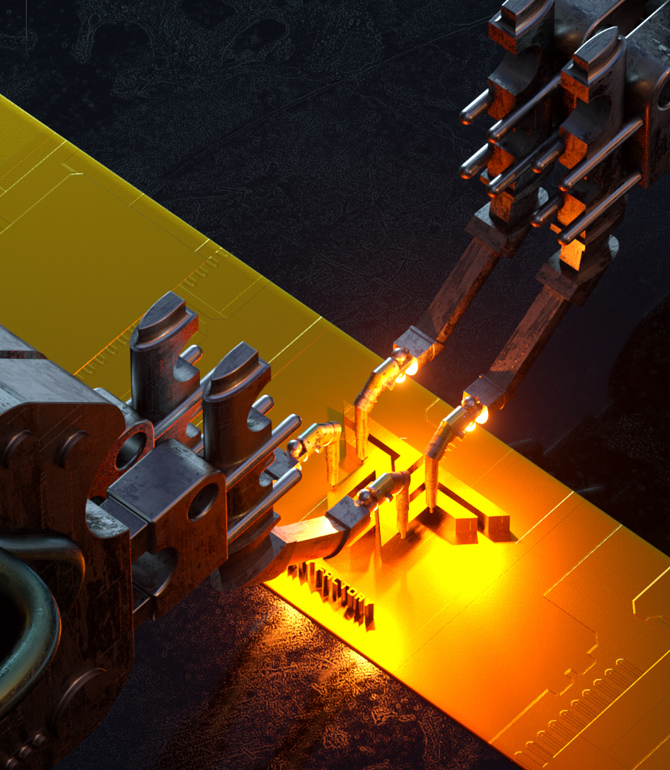

High temperature industry field

Zirconia ceramic is an advanced material with many advantages, which makes it widely used in the high-temperature industry

Thermal Barrier Coating (TBC): Zirconia ceramic is an excellent thermal barrier coating material, commonly used in high-temperature working environments such as turbines and gas turbines. By spraying zirconia ceramics on the metal surface, a high-temperature insulation layer can be formed, effectively slowing down the speed of metal components being eroded by high-temperature airflow and extending the service life of the equipment.

High temperature structural materials: Zirconia ceramics have excellent high-temperature stability and heat resistance, and are commonly used in the manufacturing of high-temperature structural components, such as furnace insulation boards, furnace lining boards, kiln refractory materials, etc. These structural materials can maintain structural stability in high-temperature environments, resist erosion and corrosion from high-temperature gases and molten materials.

Electrolytic cell ceramic membrane: In metal smelting industries such as aluminum smelting and steel smelting, zirconia ceramics are often used as ceramic membrane materials for electrolytic cells. These ceramic films can withstand high temperature and corrosion, while also having good ion conductivity, and are used for electrolyte isolation and current conduction in metal electrolysis processes.

High temperature sensors: Zirconia ceramics are also commonly used in the manufacturing of high temperature sensors, such as temperature sensors, pressure sensors, etc. These sensors can operate stably in high-temperature environments and are used to monitor and control parameter changes in high-temperature industrial processes.

High temperature coating technology: Zirconia ceramics can be used in high-temperature coating technology, such as spraying, thermal spraying and other processes, to improve the high temperature resistance and corrosion resistance of metal surfaces, and protect metal materials from the erosion of high-temperature gases and chemicals.