The Advantages of Zerodur Glass in High-Precision Applications

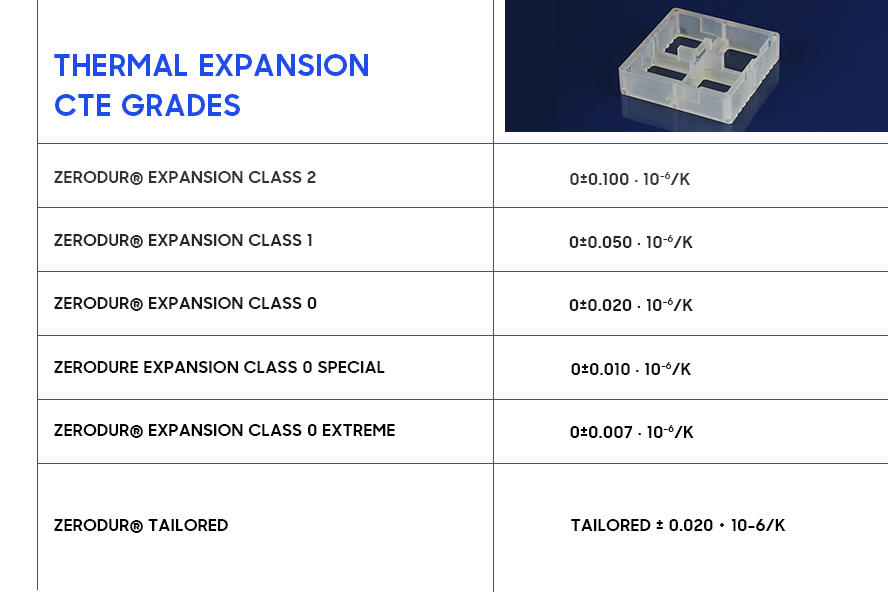

Zerodur glass-ceramic is renowned for its exceptional properties, particularly its extremely low coefficient of thermal expansion (CTE). This characteristic makes it an ideal material for high-precision applications, including mirror blanks for telescope mirrors and components in ring laser gyroscopes.

Understanding Zerodur Glass

Zerodur is a glass-ceramic material that exhibits a near-zero thermal expansion over a broad temperature range. This stability is crucial in applications where dimensional accuracy is paramount. For instance, in astronomy, telescope mirrors must maintain precise geometries to ensure optimal imaging capabilities. Any thermal expansion or contraction can lead to distortion and significant errors in observation. Zerodur’s low CTE effectively mitigates these risks, allowing astronomers to achieve clearer and more accurate images.

Applications in Telescope Mirrors

Telescope mirrors crafted from Zerodur provide several advantages:

Dimensional Stability: The near-zero CTE ensures that the mirror maintains its shape across various temperatures, critical for high-resolution imaging.

Customized Coatings: Zerodur can be paired with customized coatings to enhance reflectivity and protect the surface, improving the overall performance of telescope systems. These coatings can be tailored to specific wavelengths of light, maximizing efficiency based on the telescope's intended use.

Durability: This material’s inherent toughness and resistance to thermal shock allow it to perform reliably in diverse environmental conditions, ensuring longevity and reduced maintenance needs.

Ring Laser Gyroscopes

Zerodur is also extensively used in the manufacturing of ring laser gyroscopes. These devices rely on precise measurements of rotational motion, making thermal stability a critical factor. The low CTE of Zerodur minimizes measurement errors due to thermal fluctuations, leading to enhanced accuracy and reliability in navigation systems.

Precision Engineering: The stability of Zerodur under temperature changes means that gyroscopes can deliver consistent performance, crucial for aerospace and defense applications.

Adaptability: Customized coatings can be applied to Zerodur components in gyroscopes to optimize performance under specific operational conditions, ensuring that the devices operate efficiently regardless of environmental challenges.

Conclusion

In summary, Zerodur glass-ceramic stands out as a premier choice for high-precision applications such as telescope mirrors and ring laser gyroscopes. Its extremely low coefficient of thermal expansion, coupled with the ability to apply customized coatings, makes it an invaluable material in the fields of astronomy and navigation technology. By maintaining dimensional stability across a wide temperature range, Zerodur enables scientists and engineers to push the boundaries of precision and performance.

For those who wish to further explore the advantages of Zerodur microcrystalline glass, Jundro Ceramics can provide you with excellent Zerodur machining services, whether for customized mirror blanks or specialized gyroscope components. Welcome to contact our experts

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023