Thermal Conductivity and Insulation Properties of Ceramic Materials:Selection Guide

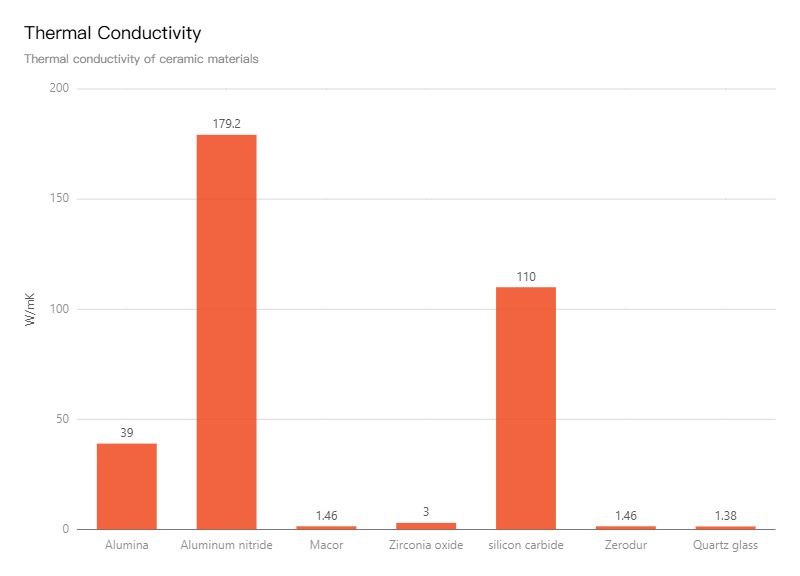

Ceramics have become an indispensable choice in modern engineering materials due to their excellent heat resistance and electrical insulation properties. However, the thermal conductivity range of ceramic materials is extremely wide, from as low as 1.5 W/mK to as high as 300 W/mK, and different materials are suitable for different application requirements. Understanding the thermal conductivity and insulation characteristics of ceramic materials is crucial for engineering design and material selection.

Measurement and Importance of Thermal Conductivity

Thermal conductivity (λ), measured in watts per meter Kelvin (W/mK), reflects the ability of a material to conduct heat. The thermal conductivity of materials is influenced by various factors, including:

Crystal structure: The atomic arrangement of a material affects the propagation of phonons, which in turn affects thermal conductivity.

Interaction force: The interaction between atoms determines the propagation speed of phonons in materials.

Temperature: As the temperature changes, the thermal conductivity of the material may also change.

In ceramic materials, thermal conductivity not only determines their performance in specific environments, but also directly affects the heat dissipation efficiency and reliability of equipment.

Common high thermal conductivity ceramic materials such as aluminum nitride (AlN), Shapal HI-M, aluminum oxide (Al ₂ O3), etc. can meet the needs of most applications and improve equipment performance. In low thermal conductivity ceramic materials such as Macor, silicate ceramics, zirconia (ZrO ₂), etc., their low thermal conductivity ensures that heat will not be conducted to sensitive components through the substrate, making them suitable for electrical insulation in high-temperature environments.

When selecting suitable ceramic materials, the following factors should be considered comprehensively

Heat dissipation requirements: In high-power electronic devices, high thermal conductivity materials (such as aluminum nitride) can effectively prevent component overheating and ensure the normal operation of the equipment.

Insulation requirements: For electrical equipment, low thermal conductivity materials (such as Macor) can not only provide electrical insulation protection, but also prevent the influence of heat on sensitive components.

Environmental conditions: In special environments (such as extreme temperature, humidity, or pressure), corresponding ceramic materials need to be selected to ensure their performance and stability.

Mechanical load: In applications that withstand mechanical stress, the strength and toughness of materials are also crucial, and suitable ceramics need to be selected according to specific applications.

The selection of ceramic materials is a complex process that requires comprehensive consideration of their thermal conductivity and electrical insulation properties. Understanding the performance of these materials in different applications can not only improve the performance and reliability of equipment, but also ensure their effectiveness in various environments. Ceramic materials always play a crucial role in high-power electronic devices, aerospace applications, and high-temperature industrial environments.

For more information about ceramic materials, please visit the Jundro Ceramic Processing website for detailed material guides and application examples. Choosing suitable ceramic materials will bring higher efficiency and reliability to your engineering projects.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023