What is High-Tech Advanced Ceramics?

High tech advanced ceramics, also known as engineering ceramics, represent a class of materials with unique properties that make them indescribable in modern technology. These ceramics offer exceptional thermal resistance, mechanical strength, and electrical insulation performance.

Unlike ceramics commonly used in construction and home furnishings, advanced ceramics are produced specifically for applications that require precision, high temperature resistance, and unique mechanical properties. We will take you to learn about the composition, properties, and applications of advanced high-tech ceramics.

Characteristics and types of Advanced ceramics

Advanced ceramics are renowned for their unique mechanical, thermal, and chemical properties. These materials are mainly composed of oxides, nitrides, and carbides, which endow them with high hardness, low thermal expansion, and high dielectric strength. In addition, they can maintain their structural integrity under extreme conditions, making them suitable for high stress environments.

Advanced Ceramics Advantages

High hardness and strength

High heat resistance

Corrosion resistance

Low thermal expansion coefficient

Good electrical insulation

low density

Types of High-Tech Advanced Ceramics

Oxide Ceramics: Including alumina (Al₂O₃) and zirconia (ZrO₂), these materials offer excellent insulation and are resistant to oxidation, making them suitable for high-temperature applications.

Carbide Ceramics: Silicon carbide (SiC) and boron carbide (B₄C) are known for their hardness and thermal conductivity, commonly used in cutting tools and armor.

Nitride Ceramics: Silicon nitride (Si₃N₄) and aluminum nitride (AlN) are valued for their strength and thermal conductivity, particularly in high-performance applications like bearings and heat sinks.

Machinable Ceramics (e.g., Macor): Macor, a machinable glass-ceramic developed by Corning, can be easily shaped using standard metalworking tools, making it highly versatile for precision applications in research and aerospace.

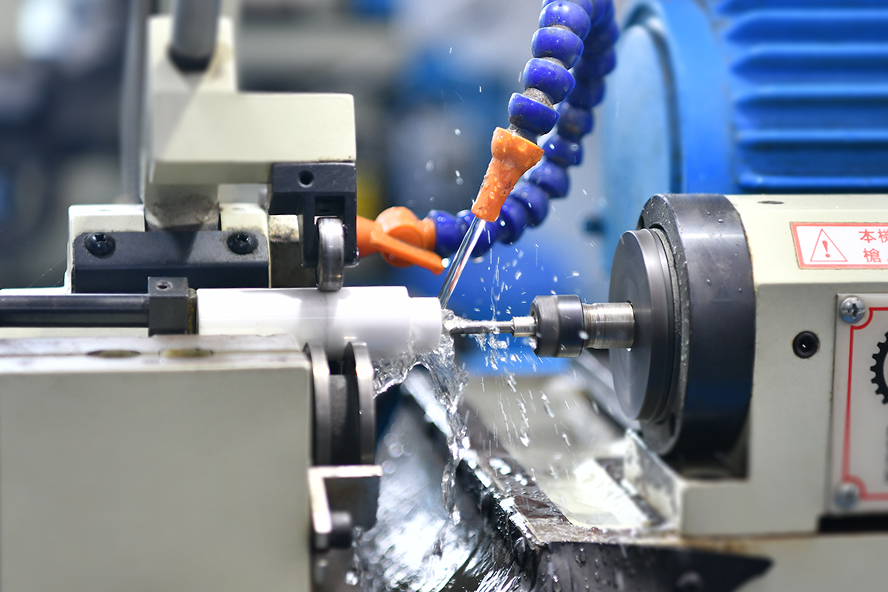

Advanced Ceramics Machining

High tech ceramic processing involves various advanced process technologies to meet the needs of precision applications, and the performance of the final product largely depends on the purity, particle size distribution, and manufacturing technology of the raw materials.

| Machining Process | |

| Powder Processing | Grinding and polishing |

| Forming Technology | CNC Machining |

| Sinter | Precision Cutting |

Applications of Advanced Ceramics

Aerospace and Defense

Advanced ceramics are essential in aerospace applications where high strength, lightweight properties, and thermal resistance are required. Ceramic thermal barrier coatings protect components in jet engines from extreme heat, while materials like silicon carbide are used in heat shields and structural components. Macor, with its machinability and dimensional stability, is often employed in satellite and spacecraft components where precise, lightweight materials are needed.

Electronics and Semiconductors

In the electronics industry, ceramics like aluminum nitride and alumina are used for substrates, heat sinks, and insulating layers. These materials provide excellent electrical insulation while managing heat dissipation, crucial in high-frequency and high-power devices. The low thermal expansion of ceramics also ensures minimal dimensional changes, which is essential for microelectronics where tolerances are tight.

Medical Technology

Ceramics are increasingly used in medical implants and devices due to their biocompatibility and wear resistance. Zirconia-based ceramics, for instance, are used in hip and knee replacements as they offer high durability and are well tolerated by the body. Additionally, ceramic coatings are applied to medical tools to enhance hardness and corrosion resistance, improving their longevity and hygiene.

Energy Sector

In energy applications, ceramics play a role in both conventional and renewable energy systems. Solid oxide fuel cells (SOFCs) use ceramics as electrolytes and electrodes due to their ability to operate at high temperatures, enhancing the efficiency of energy conversion. Ceramics also serve as thermal barriers in nuclear reactors and components in solar power plants.

Advantages and Limitations of Advanced Ceramics

Advantages

High Performance in Extreme Conditions: Ceramics’ resistance to heat and wear makes them ideal for high-stress environments.

Longevity and Durability: Unlike metals, ceramics do not corrode, which extends the lifespan of components.

Versatility: Advanced ceramics come in many types, such as machinable ceramics (Macor), thermal conductors (aluminum nitride), and biocompatible materials (zirconia), each tailored for specific applications.

Limitations

Brittleness: Ceramics tend to be brittle, which can limit their applications where flexibility is required.

High Production Costs: Advanced ceramics are more expensive to produce than traditional materials due to their precise manufacturing and high-purity raw materials.

Machining Difficulty: While machinable ceramics like Macor are an exception, most advanced ceramics require specialized equipment for shaping.

Advanced Ceramic Manufacturers

It is crucial to choose high-quality ceramic Manufacturers to ensure the stable operation of the equipment. Jundro Ceramics is located in Guangdong, China and has many years of experience in precision ceramic processing. It is a certified manufacturer with ISO 9001, ISO 14001, ISO 13485, and other certifications. Jundro Ceramics has strict requirements for the dimensional accuracy, surface roughness, and sealing compatibility of its products. We focus on the manufacturing of customized parts, starting from drawings and adapting to all types of series from short to long, thanks to our diverse and state-of-the-art machinery. Our commitment is to provide excellent service, ensure complete customer satisfaction, and value every detail in the production process.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023