The advantages of aluminum nitride ceramics in the automotive industry

The automotive industry is constantly seeking progress in materials to improve the performance, efficiency, and lifespan of vehicles. One such advancement is the utilization of aluminum nitride (AlN) ceramics. Aluminum nitride ceramics are renowned for their excellent thermal conductivity, electrical insulation performance, and mechanical strength, providing some benefits that can meet the strict requirements of modern automotive applications.

Excellent thermal conductivity

One of the outstanding properties of aluminum nitride ceramics is their high thermal conductivity, typically around 170-200W/mK. This makes AlN ceramics very suitable for applications that require efficient heat dissipation. Managing heat is crucial for maintaining performance and preventing overheating in automotive engines and power electronic devices. The ability of aluminum nitride to transfer heat from critical components helps to extend its lifespan and improve reliability. For example, in electric vehicles (EVs), AlN ceramics are used in power modules and electronic control units (ECU) to manage the large amount of heat generated, ensure stable operation, and improve the overall efficiency of the vehicle.

Excellent electrical insulation

Aluminum nitride ceramics not only have thermal conductivity, but also excellent electrical insulation performance. This dual characteristic of high thermal conductivity and electrical insulation is particularly valuable in automotive electronic products. In automotive electronic equipment, managing heat without affecting electrical integrity is crucial. AlN ceramics are used to manufacture electronic circuit substrates, which require materials that can withstand high temperatures while providing reliable electrical insulation. This makes them indispensable in the production of high-power semiconductors and integrated circuits for various automotive applications, including advanced driver assistance systems (ADAS) and information entertainment systems.

Mechanical strength and durability

Aluminum nitride ceramics exhibit significant mechanical strength and durability, which are crucial in typical harsh environments for automotive applications. Their high fracture toughness, wear resistance, and thermal shock resistance make them suitable for components undergoing extreme conditions. For example, AlN ceramics are used for sensors and actuators in the engine compartment, which must withstand high temperatures, vibrations, and mechanical stresses without degradation. This robustness ensures long-term performance and reliability, reducing the need for frequent replacement and maintenance.

Lightweight attributes

The automotive industry is constantly striving to reduce vehicle weight in order to improve fuel efficiency and performance. Aluminum nitride ceramics contribute to achieving this goal due to their relatively lower density compared to traditional metal materials. The use of AlN ceramics in components such as heat sinks, electronic substrates, and structural components can help reduce the overall weight of the vehicle. This weight reduction can improve acceleration, handling, and fuel efficiency, consistent with the industry's development towards more sustainable and energy-efficient cars.

Chemical stability and corrosion resistance

Aluminum nitride ceramics have chemical stability and exhibit excellent corrosion resistance and oxidation resistance. This characteristic is crucial for automotive components exposed to various chemicals, fuels, and environmental conditions. For example, AlN ceramics are used in exhaust systems and sensors, where they encounter corrosive gases and high temperatures. Their chemical stability ensures that these components maintain their integrity and performance over time, contributing to the overall durability and reliability of the vehicle.

Application in Power Transmission Systems and Electronics

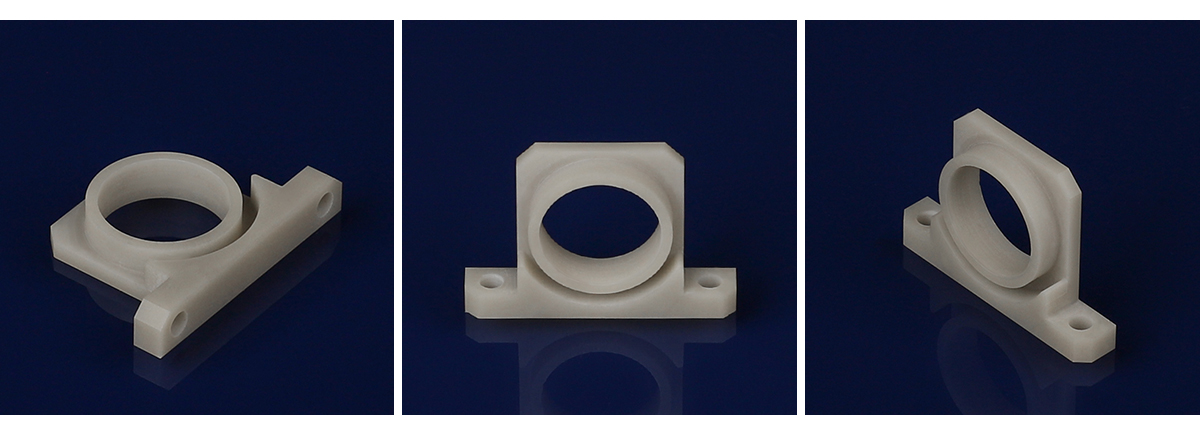

The integration of aluminum nitride ceramics has greatly benefited the power and electronic systems of modern cars. In the powertrain, AlN ceramics are used in components such as thermal management systems and high-performance bearings. These applications utilize the thermal and mechanical properties of materials to improve efficiency and reduce wear.

In the field of automotive electronics, AlN ceramics are an indispensable part of the development of power modules for electric and hybrid vehicles. The ability of this material to effectively dissipate heat while providing electrical insulation is crucial for the reliable operation of these modules under high-power loads. In addition, aluminum nitride plays a crucial role in vehicle safety and performance monitoring as a substrate for microelectromechanical systems (MEMS) sensors.

Improving the performance of electric vehicles

The rise of electric vehicles highlights the importance of advanced materials in improving automotive performance. Aluminum nitride ceramics are crucial in addressing thermal management challenges related to electric vehicle batteries and power electronics. Efficient heat dissipation is crucial for maintaining battery health and optimizing performance. AlN ceramics are used as thermal interface materials (TIM) and cooling plates within battery packs to manage heat and ensure uniform temperature distribution. This application not only improves the efficiency and lifespan of batteries, but also enhances the safety and reliability of electric vehicles.

Future prospects and innovation

The ongoing research and development in the field of ceramics are expected to further improve the performance and application of aluminum nitride. The innovation of manufacturing processes, such as additive manufacturing and advanced sintering technology, is expected to improve the cost-effectiveness and performance of AlN ceramics. These advances may expand their applications in the automotive industry, from more efficient power electronics to next-generation sensors, among others.

With the continuous development of the automotive industry towards greater electrification and autonomy, the demand for materials that can meet strict performance requirements will only increase. Aluminum nitride ceramics play a crucial role in this transition due to their unique thermal, electrical, and mechanical properties. By improving efficiency, reliability, and durability, AlN ceramics have made significant contributions to the advancement of automotive technology, paving the way for a more sustainable and high-performance future.

Aluminum nitride ceramics have many advantages and can meet the complex needs of the automotive industry. Their excellent thermal conductivity, electrical insulation, mechanical strength, lightweight performance, and chemical stability make them an ideal choice for a wide range of applications, from powertrain components to advanced electronic systems. With the continuous innovation and development of the industry, The role of AlN ceramics will become more prominent, promoting the improvement of vehicle performance, efficiency, and sustainability. The integration of aluminum nitride ceramics into automotive design is not only a progress in materials science, but also a crucial step towards the future of automotive engineering.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023