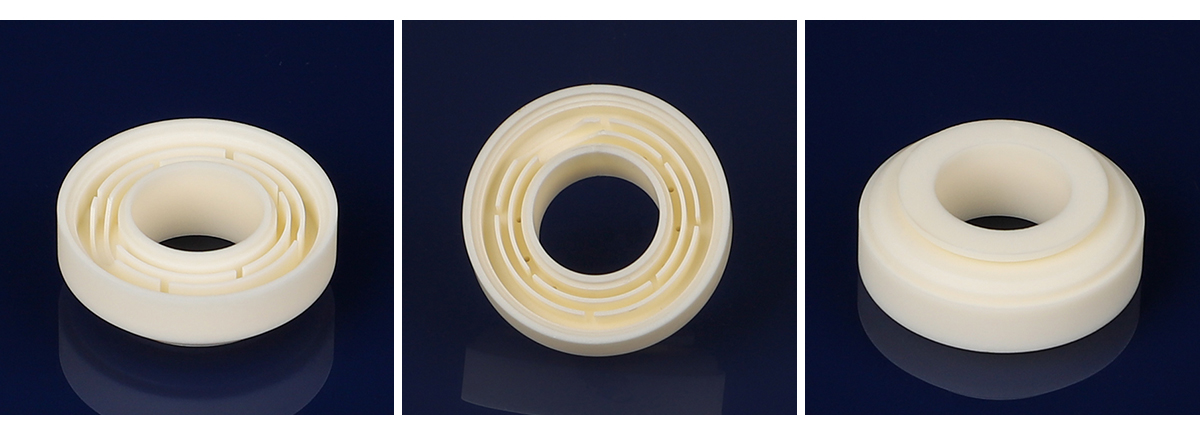

The advantages of alumina ceramic bearings in mechanical engineering

Compared with traditional metal bearings, alumina ceramic bearings are becoming increasingly popular in mechanical engineering due to their excellent performance and advantages. These advantages stem from the unique material properties of alumina, making it an ideal choice for various demanding applications.

Excellent material performance

Aluminum oxide, also known as alumina, is a ceramic material known for its excellent hardness, high thermal conductivity, excellent electrical insulation, significant wear resistance, and corrosion resistance. The inherent characteristics of alumina make it an excellent material for bearing applications in harsh environments, where traditional materials such as steel may fail.

1. Hardness and wear resistance:

The hardness level of alumina ceramic bearings is significantly higher than that of most steels. This excellent hardness translates into excellent wear resistance, ensuring a longer service life even under high loads and high-speed conditions. Mechanical systems that require long-term reliability and minimal maintenance can benefit greatly from this characteristic.

2. Corrosion and chemical resistance:

One of the prominent characteristics of alumina ceramic bearings is their resistance to corrosion and chemical erosion. Unlike metal bearings, when exposed to harsh chemicals or moisture, metal bearings can corrode or degrade, while alumina ceramic bearings can maintain their integrity. This type of resistance makes it very suitable for use in chemically aggressive environments, such as in the chemical processing industry or marine applications, where exposure to salt water can quickly damage metal bearings.

3. Thermal stability:

Aluminum oxide ceramics have excellent thermal stability and maintain their mechanical properties at high temperatures where metal bearings may soften or deform. This thermal stability is particularly beneficial in applications involving high-temperature processes, such as in industrial ovens or furnaces, as well as in aerospace engineering where temperature fluctuations are significant.

Reduce friction and improve efficiency

Another key advantage of alumina ceramic bearings is their low friction coefficient. The smooth and hard surface of alumina ceramics reduces friction between bearing surfaces, bringing several benefits:

1. Energy efficiency:

The reduction of friction in alumina ceramic bearings means that less energy is required to overcome resistance. This leads to higher overall efficiency in mechanical systems, reduced energy consumption and operating costs. In industries where energy efficiency is a critical issue, such as automotive and aerospace engineering, the use of alumina ceramic bearings can significantly save energy.

2. Lower operating temperature:

The smaller the friction, the less heat is generated during operation. The decrease in heat leads to a decrease in the operating temperature of bearings and surrounding components. The working conditions of the cooler can extend the lifespan of the entire system, reduce maintenance and downtime frequency.

Electrical insulation

Aluminum oxide ceramics are excellent electrical insulators, but metal bearings lack this characteristic. This characteristic is particularly advantageous in applications that require electrical insulation to prevent arcing or short circuits.

1. Electronics and semiconductor manufacturing:

In industries such as electronics and semiconductor manufacturing where precision and clean operations are crucial, alumina ceramic bearings are an ideal choice. Their electrical insulation performance can prevent any interference with sensitive electronic components, ensuring smooth and reliable operation.

2. Medical devices:

Medical devices, such as MRI machines and other diagnostic tools, benefit from the non-conductive properties of alumina ceramic bearings. The electrical insulation of bearings helps to maintain the integrity of sensitive medical devices, ensuring accurate results and safe operation.

Lightweight and non-magnetic

Alumina ceramic bearings are significantly lighter than metal bearings. This weight reduction is particularly beneficial in applications where weight savings are crucial, such as in aerospace and automotive engineering.

1. Aerospace engineering:

In aerospace applications, every gram is important. The use of lightweight alumina ceramic bearings can reduce the overall weight of aircraft components, thereby improving fuel efficiency and performance. In addition, their non-magnetism is crucial for avoiding interference with navigation instruments and sensors.

2. Automotive industry:

Similarly, in the automotive industry, reducing the weight of components can help improve fuel economy and reduce emissions. Aluminum oxide ceramic bearings can be used in key areas to improve vehicle performance and efficiency.

Durability and lifespan

The comprehensive properties of alumina ceramics, including hardness, wear resistance, corrosion resistance, and thermal stability, contribute to the overall durability and lifespan of bearings. In mechanical engineering where reliability and performance are crucial, the use of alumina ceramic bearings can significantly improve the service life of machinery and reduce maintenance requirements.

In heavy industrial machinery with expensive downtime, the durability of alumina ceramic bearings ensures continuous operation with minimal interruption. This reliability is particularly valuable in manufacturing plants, as maintaining consistent production is crucial.

2. Renewable energy:

In renewable energy applications such as wind turbines and solar power plants, the long-term durability of alumina ceramic bearings ensures that the system can operate efficiently with minimal maintenance. This reliability is crucial for the economic feasibility of renewable energy projects.

Alumina ceramic bearings have many advantages in mechanical engineering, including superior material properties, reduced friction, electrical insulation, lightweight structure, and excellent durability. These benefits translate into enhanced performance, efficiency, and reliability in a wide range of applications, from aerospace and automotive engineering to industrial machinery and renewable energy systems. With the advancement of technology and the increasing demand for high-performance materials, alumina ceramic bearings will play a more important role in future mechanical engineering. Its unique performance makes it a valuable component in seeking more efficient, durable, and reliable mechanical systems.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023