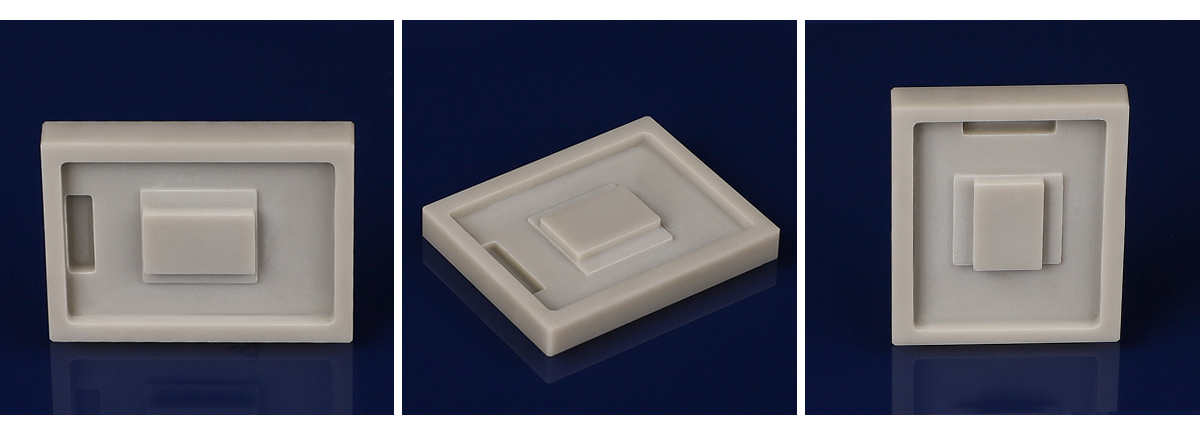

The advantages of aluminum nitride ceramics in semiconductors

In the rapidly developing field of semiconductor technology, materials science plays a crucial role in improving performance and efficiency. Aluminum nitride (AlN) is a material that has attracted much attention due to its excellent properties. AlN ceramics are renowned for their unique combination of thermal and electrical properties, and are increasingly being adopted in the semiconductor industry.

Thermal conductivity and electrical insulation

One of the most critical requirements in semiconductor components is effective thermal management. The characteristic of aluminum nitride ceramics is its high thermal conductivity, which is crucial for dissipating the heat generated by semiconductor devices. When the thermal conductivity value exceeds 170W/m · K, AlN ceramics are significantly superior to other materials such as alumina (Al2O3), which typically have a thermal conductivity of about 30W/m · K. This excellent thermal conductivity helps to maintain the operational stability and lifespan of semiconductor devices by preventing overheating.

Aluminum nitride ceramics not only have thermal conductivity, but also excellent electrical insulation performance. This combination of high thermal conductivity and electrical insulation makes AlN an ideal material for substrates and heat sinks in semiconductor devices, ensuring effective heat dissipation while preventing electrical interference.

Chemical stability and compatibility

The semiconductor manufacturing process involves harsh chemicals and extreme environments that may degrade or react with materials in use. Aluminum nitride ceramics have significant chemical stability, enabling them to resist corrosive environments and reactive substances. This characteristic is particularly beneficial in semiconductor manufacturing processes, such as etching and deposition, where the material is exposed to corrosive chemicals.

In addition, AlN ceramics have high compatibility with silicon, the main material used in semiconductors. This compatibility ensures that contamination and defects are minimized during the manufacturing process, which is crucial for maintaining the purity and performance of semiconductor devices.

Mechanical performance and durability

Mechanical strength and durability are crucial for the materials used in semiconductor equipment and components. Aluminum nitride ceramics have excellent mechanical properties, including high hardness and fracture toughness. These characteristics ensure that AlN components can withstand mechanical stress and impact during manufacturing and operation without degradation or failure.

The durability of aluminum nitride ceramics also translates to a longer lifespan of components, reducing the frequency of replacement and maintenance. This durability is particularly advantageous in high-precision applications where reliability and consistent performance are crucial.

Application of Zirconia Ceramic Pump in Semiconductor Applications

Although aluminum nitride ceramics are highly praised for their performance and application in the semiconductor industry, it is important to emphasize the complementary role of zirconia ceramic pumps. Zirconia is another advanced ceramic material widely used in pump components in semiconductor manufacturing due to its excellent wear resistance, chemical stability, and mechanical strength.

Zirconia ceramic pumps are an indispensable part of precise handling and transportation of corrosive and high-purity fluids in semiconductor processes. The excellent performance of zirconia ensures minimal pollution and degradation, while maintaining the integrity of the manufactured fluids and semiconductor devices. The synergistic effect between aluminum nitride components and zirconia ceramic pumps demonstrates the importance of advanced ceramics in optimizing semiconductor production.

Case studies and practical implementation

Several practical implementation plans emphasize the advantages of aluminum nitride ceramics in the semiconductor industry. For example, AlN substrates are widely used in the packaging of high-power electronic devices, such as power transistors and LEDs. These substrates effectively dissipate heat, enhancing the performance and reliability of the device.

In another example, aluminum nitride is used to manufacture dielectric layers for RF (radio frequency) and microwave components. The high thermal conductivity and electrical insulation of AlN ceramics ensure the optimal performance of these components, which is crucial in communication technology.

On the other hand, zirconia ceramic pumps have been applied in the chemical mechanical planarization (CMP) process, which is a key step in semiconductor chip manufacturing. The high wear resistance and chemical stability of the zirconia pump enable precise and efficient slurry transportation, ensuring a uniform wafer surface and high-quality semiconductor devices.

Future prospects and innovation

The continuous progress of semiconductor technology requires the provision of materials with excellent performance and reliability. Aluminum nitride ceramics, with their unique properties, are expected to meet these constantly evolving needs. The future innovation of AlN ceramics may include enhancing their performance through composite materials or new manufacturing technologies, further expanding their applicability in the semiconductor industry.

We are also researching and developing hybrid ceramic materials that combine the advantages of other advanced ceramics such as aluminum nitride and zirconia. This hybrid material can provide unprecedented performance characteristics, paving the way for more efficient and reliable semiconductor devices.

In summary, aluminum nitride ceramics play an indispensable role in the semiconductor industry due to their excellent thermal conductivity, electrical insulation, chemical stability, and mechanical durability. These characteristics make AlN ceramics an ideal choice for a wide range of applications, from substrates and heat sinks to dielectric layers in high-frequency components. The complementary use of zirconia ceramic pumps further improves the efficiency and reliability of semiconductor manufacturing processes, highlighting the importance of advanced ceramics in this high-tech field. With the continuous progress of semiconductor technology, the role of aluminum nitride ceramics will undoubtedly become more critical, driving innovation and performance in the next generation of electronic devices.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023