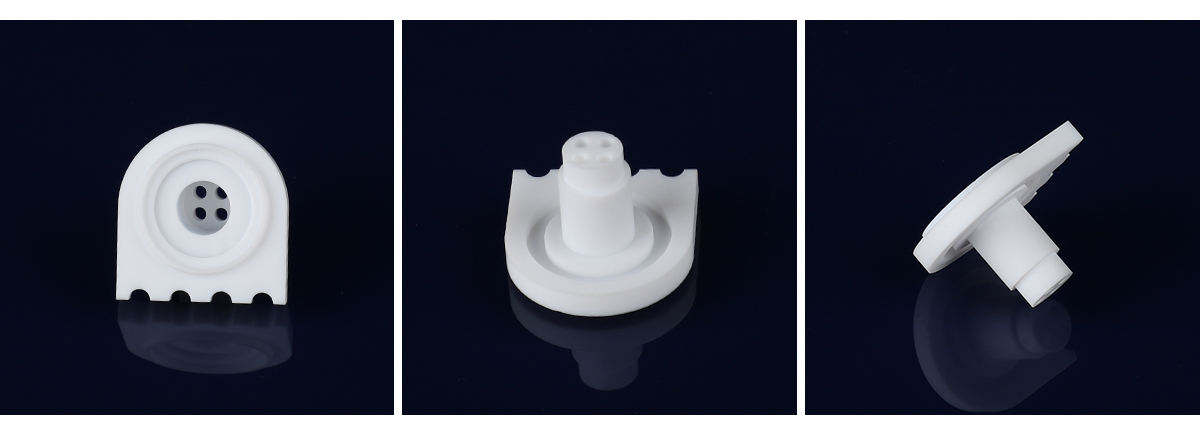

Advantages of Macror ceramic fixed brackets in aerospace applications

The aerospace industry is an industry where precision, reliability, and performance are crucial. Every component used in aerospace engineering must be able to withstand extreme conditions, including high temperatures, strong mechanical stresses, and exposure to corrosive environments. In this case, the fixed bracket made of Macor ceramic material produced by Corning has become an indispensable solution

The characteristics of Macor ceramic fixed bracket

Excellent thermal stability

One of the most critical advantages of Macror ceramic fixed brackets in aerospace is their excellent thermal stability. Aerospace components typically operate in environments with extreme temperature changes, from the cold vacuum in space to the high temperatures generated by atmospheric re-entry or engine operation. Macromolecular ceramics are renowned for their ability to maintain structural integrity and performance at temperatures exceeding 1000 ° C.

This thermal stability is crucial for some aerospace components, such as thermal protection systems, engine components, and structural supports. Unlike metals, metals can deform, weaken, or even melt at high temperatures, while Macror ceramics maintain their mechanical properties. This reliability ensures that aerospace structures remain sturdy and functional throughout their entire service life, greatly improving the safety and performance of aerospace vehicles.

High mechanical strength

In addition to thermal stability, the Macror ceramic fixing bracket also has excellent mechanical strength. These ceramics have been designed to withstand significant mechanical stress and are an ideal choice for load-bearing applications. In aerospace engineering, components are often subjected to dynamic loads, vibrations, and mechanical impacts during launch, flight, and landing phases.

Macromolecular ceramics exhibit high elastic modulus, which translates into superior stiffness and stress deformation resistance. This characteristic is particularly beneficial in components such as turbine blades, brackets, and brackets inside aircraft and spacecraft, where maintaining precise alignment and structural integrity is crucial. The high mechanical strength of Macror ceramics reduces the risk of failure, prolongs the lifespan of these components, and thus improves the overall reliability of aerospace systems.

Corrosion resistance and oxidation resistance

The aerospace environment poses significant challenges in terms of exposure to corrosive elements, including atmospheric moisture, salts, and various chemical agents. In addition, oxidation at high temperatures can cause degradation of materials used in aerospace applications. The macromolecular ceramic fixed bracket has excellent corrosion resistance and oxidation resistance, ensuring long-term durability and performance.

Unlike metals, which corrode and weaken over time, Macror ceramics are inherently resistant to chemical erosion. This resistance makes them very suitable for use in harsh environments, such as those encountered in space missions or aircraft operating on the ocean. The ability to resist oxidation at high temperatures also ensures that Macror ceramic components can maintain their structural integrity and performance even under long-term exposure to extreme conditions.

Lightweight and high specific strength

Weight is a key factor in aerospace design, as reducing the weight of components can significantly improve fuel efficiency, payload capacity, and overall performance of aircraft and spacecraft. The large-sized ceramic fixed bracket combines lightweight and high specific strength (strength to weight ratio), making it an attractive choice for aerospace engineers.

Ceramics are usually lighter than metals, and Macror ceramics are no exception. Their high specific strength means that even with weight reduction, these materials can withstand significant mechanical stress. This advantage enables aerospace designers to reduce the total weight of their vehicles without compromising safety or performance. Lighter components contribute to improved fuel efficiency, increased range, and the ability to carry additional payloads, all of which are key factors in commercial and military aerospace applications.

Accuracy and dimensional stability

Accuracy and dimensional stability are crucial in the aerospace industry, as even the slightest deviation can lead to significant performance issues or catastrophic failures. The Macro ceramic mounting bracket is manufactured with high precision to ensure tight tolerances and consistent dimensions. Their inherent dimensional stability under different thermal and mechanical conditions further enhances their applicability in aerospace applications.

During the manufacturing process, Macror ceramics can meet specific design requirements with minimal variation. This precision is crucial for components such as bearings, seals, and other critical parts that require precise fit and alignment. In addition, the dimensional stability of Macror ceramics means that these components can maintain their shape and size even under extreme operating conditions, ensuring reliable performance and reducing the need for frequent maintenance or adjustment.

Electrical insulation performance

In aerospace applications, components typically need to work reliably in environments with strict electrical requirements. The macromolecular ceramic fixed bracket has excellent electrical insulation performance and is very suitable for use in electronic and electrical systems of aerospace vehicles. This characteristic is particularly important in preventing electrical short circuits, ensuring signal integrity, and protecting sensitive electronic components from electromagnetic interference.

The application of Macror ceramics in electrical and electronic applications extends to insulators, circuit board substrates, and protective casings for electronic devices. Their ability to withstand high voltage and maintain insulation integrity under extreme conditions enhances the safety and reliability of aerospace electrical systems.

The use of Macror ceramic fixed brackets in aerospace applications provides many advantages and meets the demanding requirements of the industry. Their excellent thermal stability, high mechanical strength, corrosion and oxidation resistance, lightweight, precision, dimensional stability, and excellent electrical insulation performance make them a valuable choice for aerospace engineers.

By integrating Macror ceramic mounting brackets into aerospace design, engineers can achieve higher performance, higher reliability, and longer lifespan of critical components. These benefits translate into an improvement in the safety, efficiency, and overall mission success rate of commercial and military aerospace work. With the continuous development of the aerospace industry and technological breakthroughs, the role of advanced materials such as Macror ceramics will undoubtedly become more important. Jundro ceramics provide many customers with high-quality customized products.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023