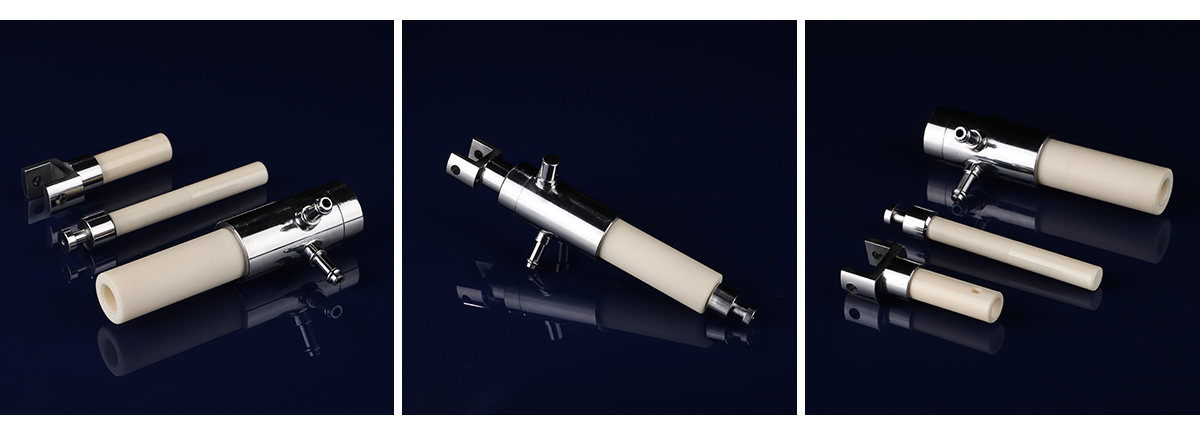

Aluminum oxide ceramic injection pump for the chemical industry

In the constantly developing chemical industry, the demand for highly durable, efficient, and corrosion-resistant equipment is crucial. Among various materials that can be used to manufacture industrial components, alumina ceramics have become the main choice, especially for injection pumps. The alumina ceramic injection pump has a series of advantages and is very suitable for the strict requirements of chemical processing.

Characteristics of Alumina Ceramic Injection Pump

Excellent corrosion resistance

One of the most significant advantages of alumina ceramic injection pumps is their significant corrosion resistance. Chemical processes typically involve the use of highly corrosive substances, which rapidly degrade traditional pump materials such as metals and polymers. Aluminum oxide ceramics are mainly composed of aluminum oxide (Al2O3) and have excellent chemical inertness. This characteristic ensures that the pump is not affected by common acids, alkalis, and other corrosive agents in the chemical industry. Therefore, the alumina ceramic injection pump can maintain its integrity and performance for a long time, reducing the need for frequent replacement and maintenance.

High hardness and wear resistance

Aluminum oxide ceramics are renowned for their excellent hardness, ranking 9th on the Mohs hardness scale, only behind diamond. This special hardness translates into excellent wear resistance, which is a key factor in the lifespan of jet pumps. In chemical processing, pumps often handle abrasive fluids, which may cause severe wear on traditional pump materials. The high wear resistance of alumina ceramics ensures that the injection pump can withstand the abrasive properties of these fluids, thereby extending its service life and reliable performance. This feature not only improves the efficiency of chemical processes, but also helps to save costs by minimizing downtime and maintenance costs.

Thermal stability and insulation performance

Chemical processes often involve extreme temperatures, which can pose challenges for many materials. Aluminum oxide ceramics have excellent thermal stability and maintain their mechanical properties at high temperatures. This makes the alumina ceramic injection pump suitable for applications involving high and low temperature limits. In addition, alumina ceramics have excellent thermal insulation performance. This characteristic is particularly beneficial in the crucial process of temperature control, as it helps to maintain the desired temperature inside the pump, ensuring consistent and efficient operation.

Excellent mechanical strength

The mechanical strength of alumina ceramics is another key advantage of injection pumps. These ceramics exhibit high compressive strength and can withstand significant mechanical stress without deformation or failure. This robustness is crucial in the chemical industry, as pumps often withstand high pressure and mechanical loads. The excellent mechanical strength of the alumina ceramic infusion pump ensures reliable performance even under challenging conditions, helping to improve the overall efficiency and safety of chemical processes.

Purity and pollution resistance

Maintaining the purity of processed materials is crucial in many chemical processes. The pollutants introduced by pump materials may affect the quality of the final product. Aluminum oxide ceramics, due to their high purity, will not leach pollutants into the fluid they treat. This characteristic is particularly advantageous in the production of high-purity chemicals and drugs, as any contamination can lead to significant quality issues. By using alumina ceramic infusion pumps, manufacturers can ensure that their processes are not affected by pollutants caused by materials, thereby protecting the integrity of the product.

Compatibility with various chemical processes

The versatility of alumina ceramics makes them suitable for a wide range of chemical processes. They are corrosion-resistant, wear-resistant, and high-temperature, which means they can be used in various environments, from acidic to alkaline, from high pressure to high temperature. This compatibility with various chemical processes makes the alumina ceramic injection pump a highly adaptable solution that can meet the unique requirements of different applications in the chemical industry.

Aluminum oxide ceramic injection pumps not only have mechanical and chemical advantages, but also help improve energy efficiency. The smooth surface of alumina ceramics reduces friction, thereby reducing the energy required for pump operation. This reduction in energy consumption translates into lower operating costs and reduced environmental footprint. In addition, the durability and lifespan of alumina ceramic pumps mean less replacement and less waste, which contributes to more sustainable industrial practices.

The alumina ceramic infusion pump represents a significant advancement in the chemical industry, providing a combination of durability, chemical resistance, thermal stability, and mechanical strength that surpasses traditional pump materials. Their ability to maintain performance under harsh conditions, combined with their purity and energy efficiency, makes them valuable assets in chemical processing applications. With the continuous progress of ceramic material research and development, the potential for more advanced and professional alumina ceramic injection pumps is urgent, which is expected to further improve the efficiency, sustainability, and performance of the chemical industry.

The integration of alumina ceramic injection pumps in chemical processes not only improves operational reliability and cost-effectiveness, but also aligns with industry sustainability and innovation goals. The continuous exploration and application of these advanced materials will play a crucial role in the future of chemical manufacturing, driving the industry to achieve higher efficiency and environmental responsibility. Jundro Ceramics is committed to the role of alumina ceramics in more industries, and provides customized alumina ceramic services to global customers.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023