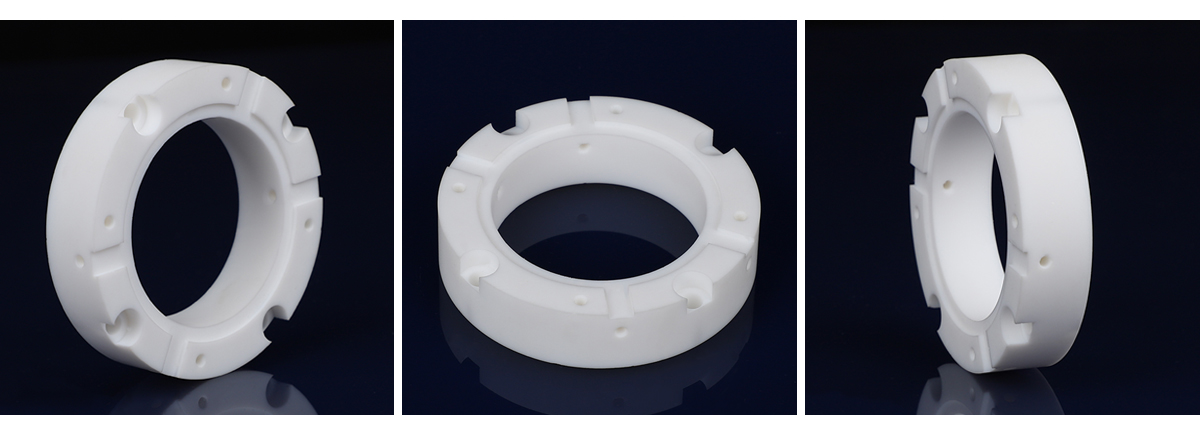

Analyzing the advantages of Macor ceramic gaskets

In industrial applications where precision and reliability are crucial, Macor ceramic washers have become key components and are highly regarded for their excellent performance and performance. Macor is an advanced ceramic material produced by Corning. These gaskets are made of Macor material and have many advantages compared to traditional gaskets, making them indispensable in various high stress environments.

The characteristics of Macor ceramic gaskets

Excellent thermal stability

One of the most significant advantages of Macror ceramic washers is their excellent thermal stability. These gaskets can withstand high and low temperatures without affecting their structural integrity or performance. Traditional gaskets are usually made of rubber, metal, or composite materials and often fail at high temperatures, leading to deformation or failure. In contrast, Macror ceramic washers can maintain their shape and function even when exposed for extended periods of time at temperatures exceeding 1000 ° C. This makes them very suitable for applications in industries such as aerospace, automotive, and power generation, as their components are often affected by strong thermal conditions.

Excellent chemical resistance

Macor ceramic washers have significant resistance to chemical corrosion and degradation. This characteristic is crucial in environments exposed to harsh chemicals and corrosive substances. For example, in the chemical processing industry, gaskets are often exposed to acids, alkalis, solvents, and other corrosive chemicals, which quickly degrade traditional gasket materials. However, the macromolecular ceramic gasket is not affected, ensuring a longer service life and consistent performance. This resistance not only extends the lifespan of the gasket, but also improves the safety and reliability of the entire system.

High mechanical strength and durability

Another significant advantage of Macor ceramic washers is their excellent mechanical strength. These washers are designed to withstand significant mechanical stress and pressure without wear or damage. Their high compressive strength and stiffness make them suitable for sealing applications in high-pressure environments, such as hydraulic systems, industrial machinery, and heavy equipment. The durability of Macror ceramic gaskets reduces maintenance costs and downtime, as they require lower replacement frequency compared to traditional gasket materials.

Precision and reliability of sealing

The precision and reliability of Macror ceramic washers are unparalleled. These gaskets are manufactured to strict standards, ensuring perfect fit and optimal sealing performance. In applications where even the slightest leakage can lead to catastrophic consequences, such as in nuclear reactors or high-performance engines, the reliability of gasket sealing is crucial. The macromolecular ceramic gasket provides a sturdy and reliable seal, preventing leakage and ensuring the effective operation of the system. Their ability to maintain consistent sealing under different conditions further highlights their advantages.

Excellent electrical insulation

Large molecule ceramic gaskets also have excellent electrical insulation performance. This characteristic is particularly beneficial in applications that require electrical insulation to prevent short circuits, leakage, or other electrical hazards. The use of ceramic materials in gaskets ensures that they can serve as effective insulators and provide protection in electrical and electronic applications. This makes them suitable for transformers, capacitors, and other electrical equipment where insulation integrity is crucial.

Environmental and Economic Benefits

The lifespan and durability of Macor ceramic washers also contribute to their environmental and economic benefits. Their extended lifespan means fewer replacements and less waste, in line with sustainable practices, and reduces environmental footprint. Economically speaking, it reduces the need for frequent gasket replacement and related maintenance costs, bringing significant savings to industries using these gaskets. The initial investment in Macror ceramic washers is often offset by their long-term performance and reliability, making them a cost-effective solution over time.

Universality of applications

The versatility of Macor ceramic washers further enhances their attractiveness. They can be customized according to the wide range of applications in different industries. Whether used in high-temperature furnaces, chemical reactors, medical equipment, or advanced manufacturing processes, these gaskets have unparalleled adaptability. They can effectively play a role in both static and dynamic sealing applications, highlighting their flexibility and wide practicality.

Macor ceramic washers represent a significant advancement in gasket technology, providing a range of advantages that make them indispensable in high-performance and high demand applications. Its excellent thermal stability, chemical resistance, high mechanical strength, and excellent electrical insulation performance make it different from traditional gasket materials. In addition, their accuracy, reliability, and versatility ensure that they meet the strict standards required in critical industrial environments.

The environmental and economic benefits brought by the use of Macror ceramic washers further highlight their value, making them a wise choice for industries seeking to improve efficiency, safety, and sustainability. Jundro Ceramics has unique processes and solid experience accumulation in the field of macro ceramic processing, providing high-quality Macor microcrystalline glass ceramic products to global customers

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023