Macor Ceramic Datasheet

Maco is a machinable ceramic material developed by Corning, which has excellent machinability and can be processed using normal metal cutting tools. It has characteristics such as low thermal conductivity, low dielectric constant, high resistance, and high voltage breakdown resistance. Let's take a look at its performance parameters below.

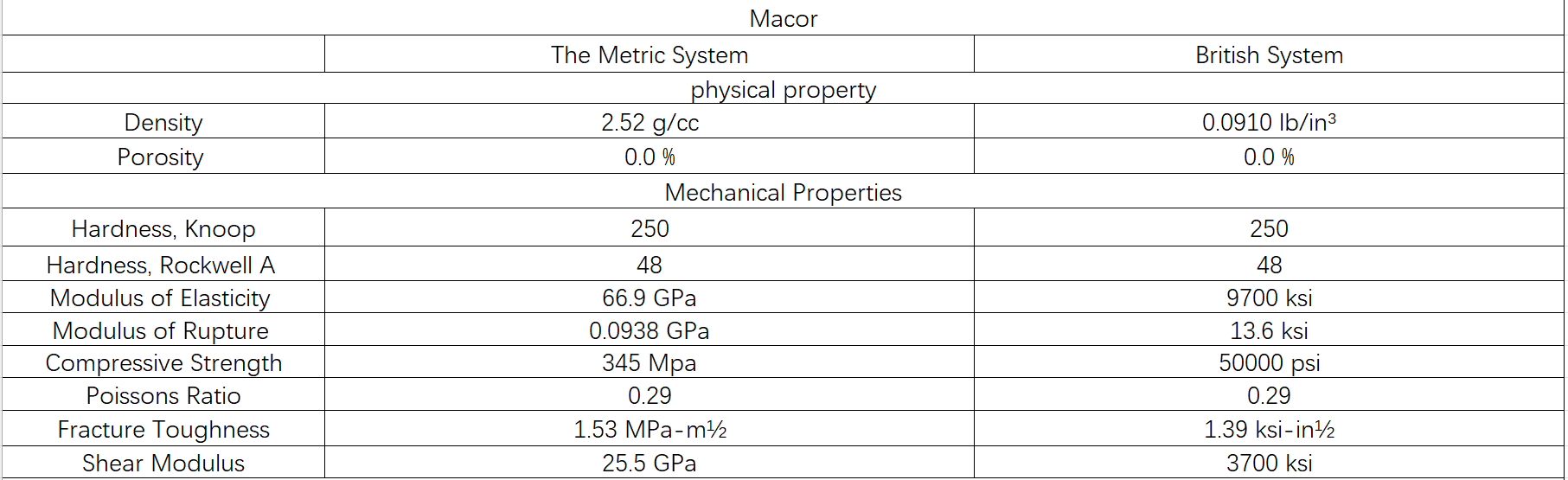

Physical and mechanical data

Hardness: The machinability of Macor ceramics depends on its hardness of 250 kg/square millimeter, with a Mohs hardness of 5-6 levels, while the Mohs hardness of most other types of ceramic materials is around 7-9 levels. This shows how excellent its machinability is.

Porosity: The porosity of Macor ceramics is 0.0%, making it an ideal choice in the field of packaging.

Elastic modulus: The elastic modulus reflects the response of a material to force and its ability to rebound after being subjected to force, and its elastic modulus is 66.9 GPa.

Fracture modulus: The fracture modulus refers to the ability of a material to resist fracture within its elastic deformation range, while that of Macor ceramics is 0.938 GPa.

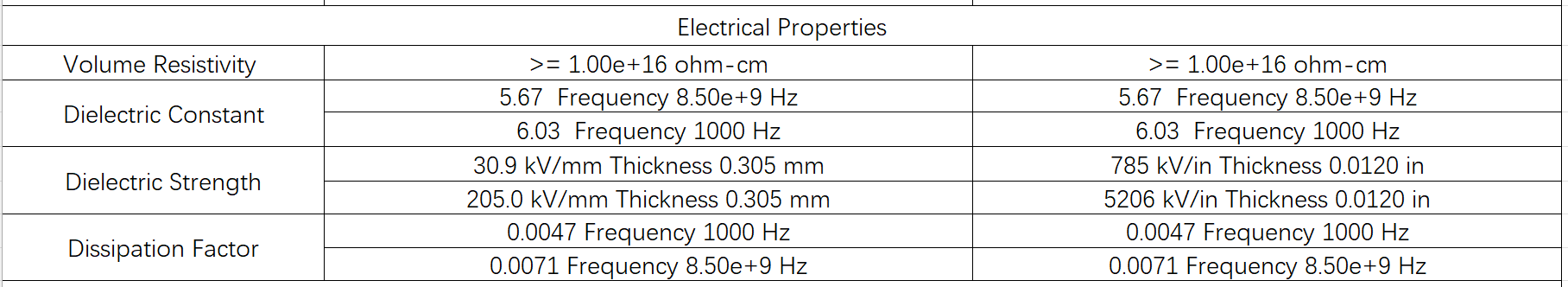

Electrical performance

Volume resistivity: Volume resistivity is one of the important parameters for measuring whether a material is conductive and its conductivity. The metric data for Macor ceramics is>=1.00e+16 ohm cm, and the same applies to the imperial system.

Dielectric constant: The dielectric constant is the main parameter that reflects the dielectric or polarization properties of a dielectric material under an electrostatic field. Therefore, the response data at different frequencies is also different, such as 5.67 Frequency 8.50e+9 Hz at 9Hz and 6.03 Frequency 1000 Hz at 1000Hz.

Thermal performance

Specific heat capacity: Specific heat capacity refers to the physical quantity of an object when absorbing or dissipating heat, measured in joules per kilogram Kelvin. The specific heat capacity of Macor ceramics is 0.790 J/g - ° C, which is 0.189 BTU/Ib - ° F because the British system uses Fahrenheit degrees.

Maximum operating temperature in the air: Operating temperature is the literal meaning, but generally we divide it into two conditions, one is full load

One type is no-load, which can reach 800 ° C at full load and 1000 ° C at no load.

The parameters of thermal performance are complex, and their data may vary depending on different temperatures and conditions.

Jundro Ceramics is a high-quality Macor ceramic processing manufacturer with years of experience in technical ceramic manufacturing processes

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023