The advantages of zirconia ceramic pumps in medical equipment

In the medical field, the reliability and accuracy of equipment are crucial. With technological progress constantly breaking through possible limits, materials science has played a crucial role in improving the performance and durability of medical equipment. Zirconia ceramics are one of the most prominent materials in this field and have been widely used in various medical equipment, especially in pumps.

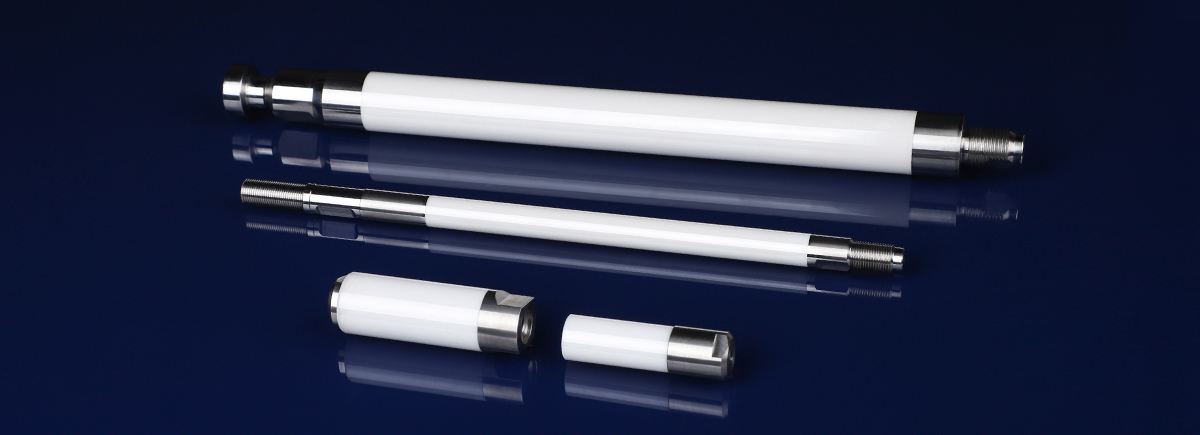

Excellent mechanical performance

Zirconia ceramics, especially zirconia dioxide (ZrO2), are renowned for their excellent mechanical properties. These ceramics exhibit high strength and fracture toughness, significantly higher than other ceramic materials. This durability makes the zirconia ceramic pump highly durable and capable of withstanding typical harsh environments in medical applications. Their high mechanical strength ensures that these pumps can operate under high pressure without deformation or failure, making them an ideal choice for reliability non negotiable critical medical procedures.

Chemical inertness and biocompatibility

One of the most significant advantages of zirconia ceramics is their chemical inertness. In medical applications, it is crucial that materials do not react with body fluids or drugs, as such reactions may endanger the safety and effectiveness of treatment. The zirconia ceramic pump is highly resistant to corrosion and chemical reactions, ensuring its integrity and not contaminating the fluid it processes. In addition, zirconia has biocompatibility, which means it will not cause adverse immune reactions when in contact with biological tissues. This characteristic is crucial for pumps used in drug delivery systems and blood circulation equipment, where interaction with the human body is inevitable.

Accuracy and stability

The accuracy and stability of medical equipment are crucial for accurate diagnosis and treatment. Due to its low wear rate and minimal thermal expansion, zirconia ceramic pumps perform excellently in providing stable performance over the long term. These characteristics are crucial in applications that require precise fluid control, such as in dialysis machines and infusion pumps. The minimum thermal expansion of zirconia ceramics ensures that the pump can maintain its dimensional stability even at different temperatures, which is crucial for maintaining the accuracy of the fluid delivery system.

Schott Zerodur microcrystalline glass integration

In addition to zirconia ceramics, the integration of Schott Zerodur microcrystalline glass in medical devices further enhances the performance of these devices. Zerodur is renowned for its near zero thermal expansion properties, making it an excellent supplementary material in environments where temperature stability is crucial. When used with zirconia ceramic pumps, Zerodur can help maintain precise alignment and calibration of components, ensuring consistent and reliable performance.

The optical properties of Zerodur also make it valuable in medical imaging devices where clarity and accuracy are crucial. The combination of Zerodur glass and zirconia ceramics can develop advanced diagnostic tools with unparalleled accuracy and reliability.

Application in medical equipment

Zirconia ceramic pumps are used in various medical equipment, and each pump benefits from the unique performance of this material. Some key applications include:

1. Dialysis machine: Dialysis requires a precise and reliable pump to effectively filter blood. Zirconia ceramic pumps ensure consistent performance and service life, reducing the risk of equipment failure during critical processing.

2. Infusion pumps: These devices transport liquids such as drugs and nutrients to the patient's blood. The accuracy and chemical inertness of zirconia ceramic pumps ensure accurate dosage and prevent contamination, which is crucial for patient safety.

3. Blood circulation equipment: Among devices such as cardiopulmonary machines that temporarily take over heart and lung function during surgery, zirconia ceramic pumps provide the necessary durability and biocompatibility to process blood without causing adverse reactions.

4. Drug delivery system: Advanced drug delivery systems require pumps that can handle various drugs without degrading or reacting with them. The zirconia ceramic pump meets these requirements to ensure safe and effective drug delivery.

5. Analytical instruments: Accurate fluid processing is crucial for accurate results in laboratory environments. Zirconia ceramic pumps are used in instruments such as chromatographs and spectrometers, and their stability and chemical resistance are highly valued.

Extend service life and reduce maintenance

The durability of zirconia ceramic pumps means that medical equipment has a longer service life and lower maintenance requirements. This lifespan is particularly advantageous in the medical field, as equipment downtime may lead to significant interruptions in patient care. Wear resistance and corrosion resistance mean that zirconia ceramic pumps do not require frequent replacement and maintenance, thereby reducing operating costs and improving the reliability of medical equipment.

Environmental and economic factors

The use of zirconia ceramic pumps is also in line with environmental and economic considerations. Long service life, reduced demand for maintenance and replacement of components, helps reduce waste generation, and supports sustainable practices in the healthcare industry. In addition, over time, the high performance and reliability of these pumps can save costs as they minimize the need for frequent maintenance and replacement.

The zirconia ceramic pump represents a significant advancement in the field of medical equipment, providing unparalleled mechanical strength, chemical inertness, and biocompatibility. Their integration with various medical devices improves the accuracy, reliability, and safety of treatment, ultimately improving the prognosis of patients. The supplementary use of Schott Zerodur microcrystalline glass further enhances the performance of these pumps, providing the necessary temperature stability and optical clarity for advanced medical applications. With the continuous development of the healthcare industry, the role of high-performance materials such as zirconia ceramics and Zerodur glass will undoubtedly become increasingly important, driving innovation and improving the quality and efficacy of healthcare.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023