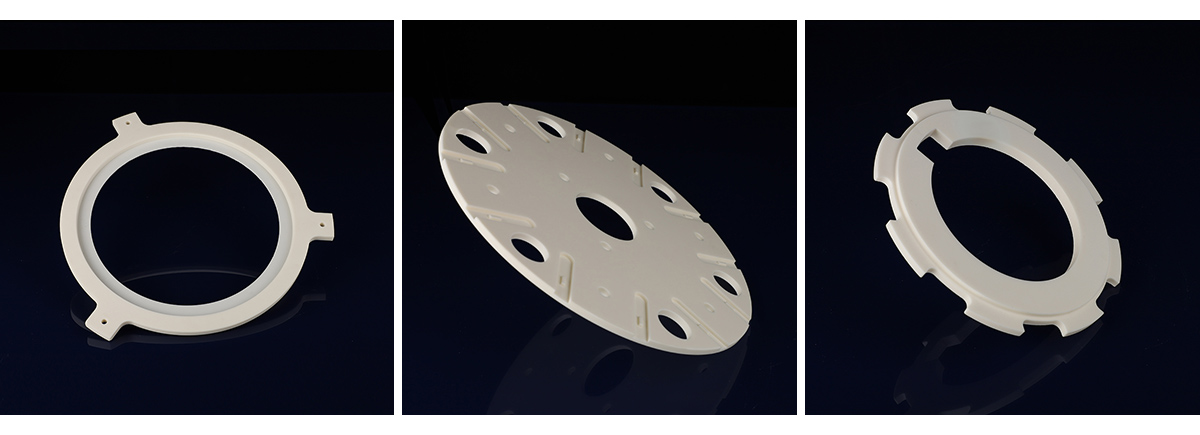

Alumina ceramics, also known as alumina (Al2O3) ceramics, are one of the most widely used types of advanced ceramics. Aluminum oxide ceramics are renowned for their excellent mechanical, thermal, and electrical properties, playing a crucial role in various industries from electronics to medical equipment.

Aluminum oxide, also known as aluminum oxide, is a compound composed of aluminum and oxygen. In its crystal form, it is called corundum, and when added with trace elements, it becomes gemstones such as sapphire and ruby. Aluminum oxide ceramics are derived from high-purity aluminum oxide powder and are widely used due to their excellent performance characteristics. The purity of aluminum oxide used can range from 85% to 99.9%, and higher purity levels are essential for applications that require enhanced performance.

Mechanical performance

Aluminum oxide ceramics are renowned for their impressive mechanical strength and hardness. They exhibit high compressive strength, typically between 2000 and 4000 MPa, making them suitable for high stress applications. Their hardness is about 9 on the Mohs hardness scale, second only to diamonds, making them effective in resisting wear. These characteristics make alumina ceramics an ideal choice for cutting tools, abrasives, and wear-resistant components.

Thermal performance

One of the most significant features of alumina ceramics is their excellent thermal stability. They can withstand high temperatures up to 1700 ° C without significant degradation. Their high thermal conductivity helps with heat dissipation, making them valuable in applications that require efficient thermal management. In addition, their low coefficient of thermal expansion ensures dimensional stability under temperature fluctuations, which is crucial for precision engineering components.

Electrical characteristics

Aluminum oxide ceramics are a special type of electrical insulator, which is why they are indispensable in the electronic industry. They have high dielectric strength, allowing them to withstand high voltages without breakdown. Their low conductivity ensures effective insulation, prevents leakage, and improves the performance and safety of electronic devices. The dielectric constant of alumina ceramics is usually around 9.8, which makes them suitable for capacitors and other electronic components.

chemical property

Aluminum oxide ceramics are known for their significant chemical inertness, which enables them to resist corrosion and chemical erosion from most acids, bases, and solvents. This chemical stability is particularly valuable in harsh environments where materials are exposed to corrosive chemicals. Therefore, alumina ceramics are widely used in chemical processing equipment, laboratory tools, and protective coatings.

Biocompatibility

High purity alumina ceramics have biocompatibility, which means they are non-toxic and will not cause adverse biological reactions when in contact with living tissues. This characteristic makes it suitable for medical applications, including dental implants, joint replacement surgery, and bone screws. Their inertness and stability in the body ensure long-term performance and compatibility with human tissues.

The production of alumina ceramics involves several key steps to ensure the expected performance and performance of the final product. These steps include powder preparation, molding, and sintering.

Powder preparation

High purity alumina powder is the raw material for alumina ceramics. These powders are typically produced through the Bayer process, which involves refining bauxite to obtain aluminum hydroxide, which is then calcined to produce alumina. Then, the obtained powder is processed to obtain the required particle size and distribution, which is crucial for the subsequent molding and sintering steps.

mould

Use various techniques to shape the prepared alumina powder into the desired form. Common forming methods include:

-Pressing: The powder is compacted into the mold under high pressure, forming a dense green body.

-Injection molding: Mix alumina powder with adhesive and inject it into the mold to manufacture complex shapes with high precision.

-Squeezing: Powder is forced through a mold to produce a continuous and growing shape, such as rods and tubes.

-Sliding casting: Pour aluminum oxide powder slurry into a porous mold, where it absorbs the liquid phase and leaves a solid ceramic body.

Sintering

Sintering is a key step in the production of alumina ceramics. The formed green body is heated to a high temperature in a controlled atmosphere, usually between 1400 ° C and 1700 ° C. During the sintering process, particles combine to form a dense solid ceramic with enhanced mechanical and thermal properties. The sintering process can be customized according to application requirements to achieve specific microstructures and properties.

The unique performance combination exhibited by alumina ceramics makes it suitable for wide applications in various industries.

mechanical engineering

In mechanical engineering, alumina ceramics are highly valued for their wear resistance and strength. They are used for cutting tools, bearings, and wear-resistant components in machinery. Their hardness and ability to maintain strength at high temperatures make them suitable for applications in the automotive and aerospace industries, where durability and performance are crucial.

Electronic and Electrical Engineering

Aluminum oxide ceramics are widely used in the electronic industry due to their excellent insulation performance. They serve as substrates for electronic circuits, providing a stable platform for the installation and interconnection of components. Their high dielectric strength and thermal conductivity make them an ideal choice for high-voltage and high-frequency applications. In addition, alumina ceramics are also used to manufacture spark plugs, insulators, and microwave devices.

Chemical and Environmental Applications

Alumina ceramics' chemical inertness makes them suitable for use in harsh chemical environments. They are used in the construction of chemical processing equipment, such as reactors, pipelines, and valves, where resistance to corrosion and chemical attack is essential. Additionally, alumina ceramics are used in environmental applications, such as filtration systems and catalyst supports, due to their stability and durability in aggressive conditions.

Future trends and developments

The ongoing research and development in the field of advanced ceramics are continuously improving the performance of alumina ceramics and expanding their applications. The innovation in nanotechnology and materials science has led to the development of alumina ceramics with improved mechanical, thermal, and electrical properties. These advances have opened up new possibilities for their application in emerging technologies, such as advanced electronic products, renewable energy systems, and biomedical devices.

Aluminum oxide ceramics continue to be the cornerstone of advanced material engineering due to their outstanding mechanical, thermal, electrical, and chemical properties. Its versatility and performance make it indispensable in a wide range of applications, from industrial machinery to cutting-edge medical equipment. With the advancement of research and technology, the potential of alumina ceramics will continue to expand, bringing new innovations and applications, which will further enhance their significance in modern technology and industry. The ongoing exploration of nanotechnology, additive manufacturing, and composite materials is expected to unleash the greater capabilities of alumina ceramics, ensuring their continued relevance and importance in the future.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023