Industrial Application of Zirconia Ceramics

Zirconia ceramics, also known as zirconia (ZrO2) ceramics, have become a key material in the industrial field due to their excellent mechanical properties, chemical resistance, and thermal stability. These advanced ceramics are widely used in various industries, and their unique characteristics make their performance reach a level that cannot be compared to other materials.

Mechanical properties and structural applications

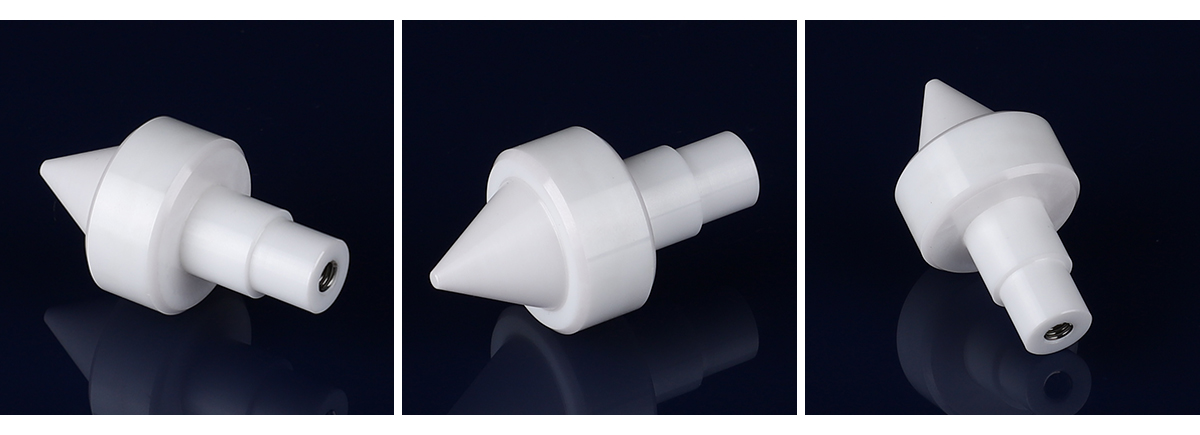

Zirconia ceramics are renowned for their high fracture toughness and mechanical strength, making them suitable for applications where durability and reliability are crucial. One of the main industries that utilize these characteristics is the manufacturing of cutting tools and molds. Compared with traditional materials, zirconia based cutting tools have excellent edge retention and wear resistance. This will extend the tool life, reduce downtime, and improve the accuracy of the machining process. In addition, the high hardness and toughness of this material make it an ideal choice for mechanical wear parts, including bearings, valve components, and bushings in pumps and pipelines.

Thermal stability and high-temperature applications

The thermal stability of zirconia ceramics is another characteristic with wide industrial applications. They can withstand extreme temperatures without losing structural integrity, which is crucial for components used in high-temperature environments. In the aerospace and defense fields, zirconia ceramics are used as insulation coatings for turbine blades and engine components. These coatings protect critical components from thermal degradation, improving the efficiency and lifespan of jet engines and other high-performance systems.

In the field of energy, zirconia ceramics play a crucial role in the development of solid oxide fuel cells (SOFCs). SOFC operates at high temperatures and requires materials that can maintain its performance without degradation. The excellent ion conductivity and thermal stability of zirconia make it an ideal electrolyte material for these fuel cells, contributing to efficient and sustainable energy production.

Chemical resistance and corrosive environment

Industries that handle highly corrosive environments, such as chemical processing and petrochemicals, benefit greatly from zirconia ceramics. Their excellent resistance to acids, bases, and other corrosive substances ensures the long-term performance and reliability of components exposed to harsh chemical conditions. Zirconia ceramic lining is commonly used in chemical reactors, storage tanks, and pipeline systems to prevent corrosion and extend the service life of these critical infrastructure.

Electrical characteristics and electronic applications

Zirconia ceramics have also been applied in the electronic industry due to their unique electrical properties. They are used as insulators and substrates in electronic devices, providing excellent electrical insulation and thermal management. In addition, the ability of this material to conduct oxygen ions makes it valuable in oxygen sensors and lambda probes, which is crucial for monitoring and controlling the air-fuel ratio of internal combustion engines. This application is particularly important for automotive and industrial engines, where efficient fuel combustion and emission control are crucial.

Biomedical applications

Although zirconia ceramics are mainly an industrial material, they have also made significant progress in the biomedical field, especially in the development of dental and orthopedic implants. The biocompatibility, strength, and aesthetics of zirconia make it an ideal material for dental crowns, bridges, and implants. In orthopedics, zirconia is used in joint replacement components such as hip and knee prostheses due to its wear resistance and compatibility with the human body. These medical applications, although not purely industrial applications, demonstrate the versatility and widespread use of zirconia ceramics.

Zirconia ceramics are the cornerstone of modern industrial applications, with unparalleled mechanical strength, thermal stability, chemical resistance, and unique electrical properties. From cutting tools and high-temperature coatings to fuel cells and electronic components, zirconia ceramics have achieved crucial progress in industrial efficiency, sustainability, and performance. Jundro ceramics in zirconia ceramics, alumina ceramics, Macror has been engaged in the processing of advanced ceramic materials such as ceramics for many years and has rich processing experience, providing customized processing services to global customers.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023