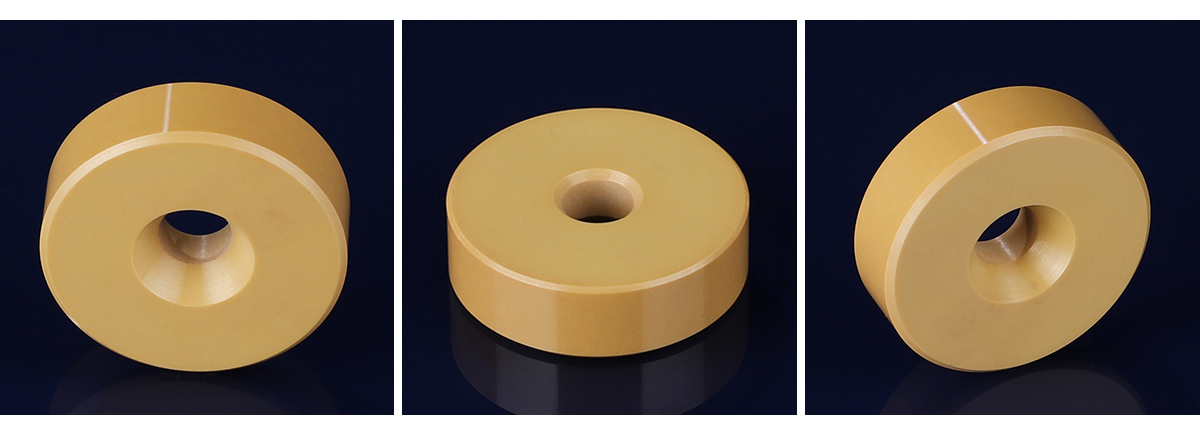

Practical Achievements of Magnesium Stabilized Zirconia Ceramics

Magnesium stabilized zirconia (MSZ) ceramics represent significant progress in the field of materials science, particularly in high-performance ceramics. This type of ceramic utilizes the unique properties of zirconia (ZrO2) and magnesium oxide (MgO) to create a material that performs well in various industrial applications. The combination of these oxides enhances the mechanical strength, thermal stability, wear resistance, and corrosion resistance of ceramics, making them indispensable in many high stress environments.

Properties of Magnesium Stabilized Zirconia Ceramics

The performance of MSZ ceramics comes from the inherent characteristics of zirconia and magnesium oxide. Zirconia is a material known for its high fracture toughness, and magnesium oxide is a stabilizer. When magnesium oxide is added to zirconia, it stabilizes the cubic phase of zirconia at room temperature, preventing phase transitions that may cause material degradation. The main properties of MSZ ceramics include:

1. High fracture toughness and strength: MSZ ceramics exhibit extraordinary fracture toughness, significantly higher than traditional ceramics. This makes them suitable for applications that require materials that can withstand high mechanical stress and impact.

2. Thermal stability: These ceramics maintain their structural integrity at high temperatures, making them an ideal choice for high-temperature applications such as engines and turbines. The coefficient of thermal expansion is also relatively low, thereby reducing the risk of thermal shock.

3. Wear resistance: MSZ ceramics have high wear resistance and wear resistance, thereby extending the lifespan of components made of this material. This characteristic is particularly beneficial in environments where components are subjected to constant friction.

4. Corrosion resistance: The chemical inertness of MSZ ceramics provides excellent corrosion resistance and chemical erosion resistance, making it suitable for use in harsh chemical environments.

5. Biocompatibility: Due to its inertness, MSZ ceramics have biocompatibility, making them suitable for medical applications such as dental implants and prosthetics.

Actual achievements in industrial applications

The unique properties of magnesium stabilized zirconia ceramics have achieved significant practical achievements in various industries. Some of the most prominent applications include:

1. Automotive industry

MSZ ceramics are also widely used in the automotive industry, especially in the manufacturing of high-performance engine components. For example, an MSZ based oxygen sensor is crucial for monitoring and regulating the oxygen levels in exhaust gases, ensuring optimal engine performance and reducing emissions. In addition, MSZ ceramics are used for spark plugs and brake components, and their wear resistance and thermal stability help improve performance and extend service life.

2. Aerospace industry

In the aerospace industry, The high strength to weight ratio and thermal stability of MSZ ceramics make them very suitable for key components such as turbine blades, insulation coatings, and exhaust systems. These components must be able to withstand extreme temperatures and mechanical stresses, and MSZ ceramics can provide the necessary durability and performance. The use of MSZ ceramics in these applications improves fuel efficiency, reduces maintenance costs, and enhances the overall performance and lifespan of aircraft engines.

3. Medical field

In the field of medicine, The biocompatibility and mechanical properties of MSZ ceramics make them suitable for various implants and prosthetics. Dental implants made of MSZ ceramics are known for their strength, durability, and aesthetic appeal, which are very similar to natural teeth. Orthopedic implants such as hip and knee replacements also benefit from the wear resistance and biocompatibility of MSZ ceramics, thereby improving patient treatment outcomes and extending the lifespan of the implants.

Magnesium stabilized zirconia ceramics have been proven to be key materials in various high-performance applications due to their excellent mechanical properties, thermal stability, wear resistance, and corrosion resistance. The practical achievements of MSZ ceramics in industries such as aerospace, automotive, medical, energy, manufacturing, and electronics highlight their versatility and reliability. With the continuous progress of technology, The role of MSZ ceramics is expected to expand, driving innovation and improving performance in many fields. The synergistic effect between materials science and practical applications highlights the importance of continuing to research and develop magnesium stabilized zirconia ceramics, paving the way for future breakthroughs and enhancing industrial capabilities. Jundro Ceramics has been providing customized services for magnesium stabilized zirconia for many years, with profound processing technology to provide reliable processing services for global customers.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023