Macor Ceramic in Aerospace and Aviation Applications

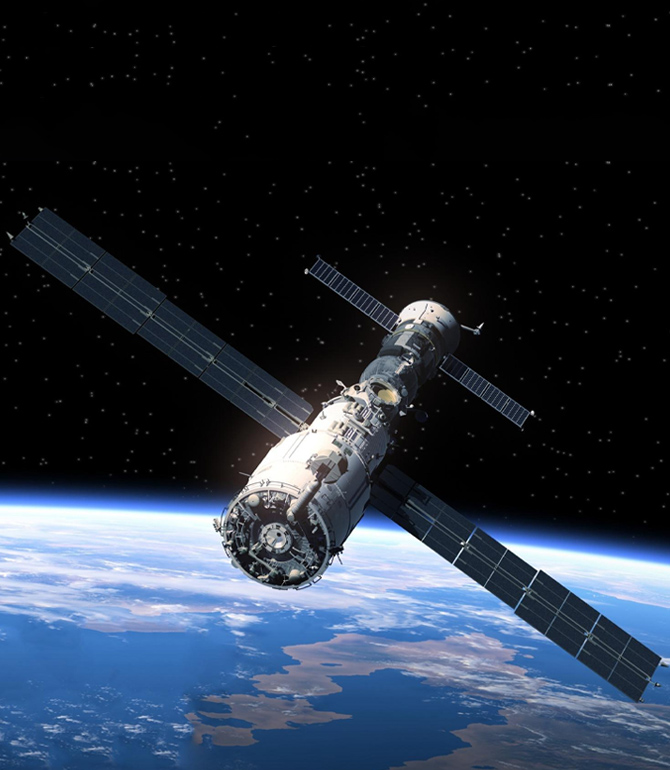

Application of Macor Glass Ceramics in Aerospace

Macor glass ceramics, as machinable materials produced by Corning, are widely used in the aerospace industry due to their excellent mechanical properties and ease of processing. The following are its main applications:

1. Electronic packaging

In spacecraft and satellites, Macor is used to protect sensitive electronic components, resist high temperatures, radiation, and other external factors, ensuring the normal operation of equipment in extreme environments.

2. Thermal insulation structural components

Macor is often used as a structural material in thermal protection systems, and its high temperature resistance makes it play a key role in spacecraft thermal management systems.

3. Supporting structure

Macor is used to manufacture support structures, mounting brackets, and isolators in aircraft, rocket engines, and satellites, providing excellent mechanical stability and heat resistance.

4. Optical instruments and sensor components

Due to its low thermal expansion coefficient and stability, Macor is widely used as a support frame and alignment fixture for optical instruments and sensors, ensuring accuracy under extreme conditions.

Future Development Trends

With the continuous advancement of aerospace technology, the demand for high-performance materials is also increasing. Macor glass ceramics are expected to play an important role in future deep space exploration and high-precision aviation equipment.

Jundro Ceramics focuses on providing high-quality Macor ® Materials and processing services to meet various precision machining needs, from design to large-scale production. Our services include material selection, precision machining, surface treatment, and inspection to ensure optimal performance in each application.