In the rapidly evolving semiconductor industry, silicon carbide (SiC) is emerging as a game-changing material. Its unique properties enable superior performance, particularly in high-power and high-frequency applications. As electronic devices continue to shrink in size while increasing in functionality, the demand for more efficient and robust semiconductor materials has never been higher. Silicon carbide meets these needs, offering advantages that outperform traditional silicon-based semiconductors.

Key Properties of Silicon Carbide for Semiconductors

Wide Bandgap: Silicon carbide has a bandgap of 3.26 eV, compared to 1.12 eV for silicon. This higher bandgap allows SiC-based devices to operate at much higher voltages, frequencies, and temperatures, making it an ideal choice for high-power applications.

High Thermal Conductivity: SiC exhibits superior thermal conductivity, enabling efficient heat dissipation. This is crucial in applications like power electronics, where managing heat is key to performance and longevity.

High Electric Field Strength: SiC can sustain electric fields up to 10 times greater than silicon. This makes it suitable for high-voltage components, minimizing the size of the devices while improving energy efficiency.

Radiation Resistance: SiC's robust atomic structure provides excellent resistance to radiation, which is particularly beneficial in aerospace and nuclear applications where components are exposed to high radiation levels.

Applications of Silicon Carbide in Semiconductors

Power Electronics: The ability of SiC to operate at higher voltages and temperatures makes it a superior choice for power electronics in applications such as electric vehicles (EVs), renewable energy systems, and industrial power supplies. Silicon carbide's high efficiency translates into reduced energy losses, enabling longer battery life and faster charging times in EVs.

RF and Microwave Devices: SiC is increasingly being used in radio frequency (RF) and microwave devices, where high frequency and power handling are critical. It is especially useful in wireless communication, radar systems, and satellite communications, providing better performance in terms of power efficiency and signal integrity.

High-Temperature Applications: SiC-based semiconductors can operate in extreme temperature environments, making them suitable for aerospace, automotive, and energy exploration industries. For instance, SiC devices in automotive engine control systems im

prove fuel efficiency and reduce emissions due to their ability to perform in hot environments.

LED Technology: SiC is used as a substrate in manufacturing light-emitting diodes (LEDs). Its properties allow for brighter, more efficient LEDs with a longer lifespan compared to those made with traditional silicon substrates.

Solar Inverters: Silicon carbide's ability to handle high voltages and temperatures with minimal energy loss makes it an excellent material for solar inverters, leading to higher energy conversion efficiency and reduced cooling requirements.

Silicon Carbide vs. Silicon: A Comparative Advantage

When comparing silicon carbide to traditional silicon, SiC consistently outperforms in high-power and high-frequency applications. Although SiC is more expensive to produce, its benefits in terms of performance, energy efficiency, and device longevity outweigh the initial costs. As the demand for more efficient and compact power solutions grows, the semiconductor industry is rapidly adopting SiC technology, particularly in electric vehicles, industrial automation, and renewable energy sectors.

Future Prospects for SiC in Semiconductors

With the continuous growth in demand for higher efficiency and performance in electronic devices, silicon carbide is poised to play a crucial role in the future of semiconductors. As manufacturing processes improve and costs decrease, the adoption of SiC in various industries is expected to accelerate. This includes expanding its role in the automotive, aerospace, and telecommunications industries, driving innovation and setting new standards for semiconductor technology.

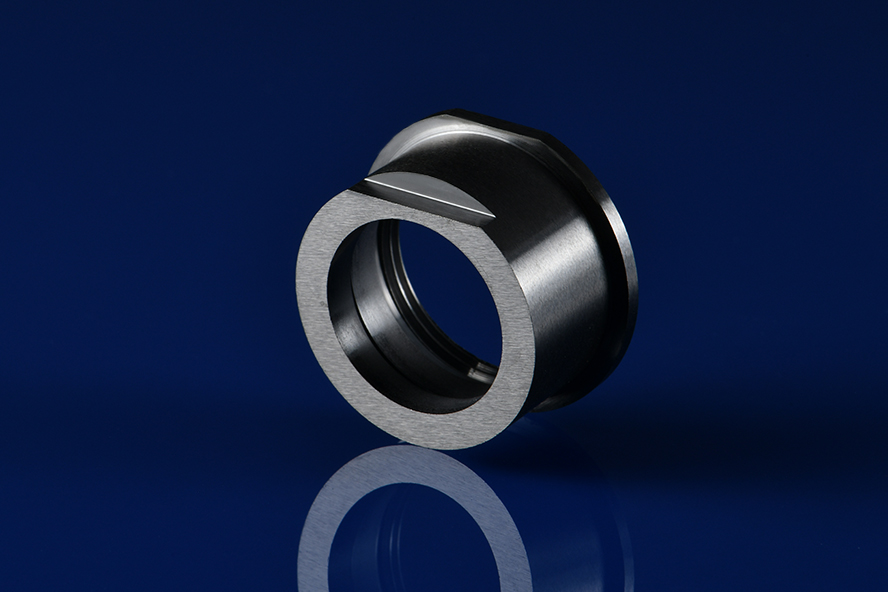

Jundro is a leading global supplier of technical ceramics, specializing in the processing and manufacturing of semiconductor ceramic materials. We mainly process semiconductor packaging substrates

Ceramic components such as laser diodes, microwave device substrates, insulated gate bipolar transistor modules, antenna oscillators, and power electronic components

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023