Zerodur Glass-Ceramic: The Ultimate Solution for Precision Applications

Introduction to Zerodur Glass-Ceramic

Zerodur glass-ceramic is an advanced material known for its exceptional thermal stability and low thermal expansion coefficient. Developed for high-precision applications, Zerodur is particularly favored in fields such as optics, aerospace, and high-tech engineering. Its unique properties make it an ideal choice for components that require consistent performance under varying environmental conditions.

Key Properties of Zerodur Glass-Ceramic

Thermal Stability Zerodur exhibits minimal dimensional changes across a wide temperature range. This stability is crucial in applications where temperature fluctuations could compromise precision, such as in telescopes or laser systems.

Low Thermal Expansion With a coefficient of thermal expansion comparable to that of metals, Zerodur minimizes the risk of warping or distortion during manufacturing and operation. This feature enhances its reliability in high-precision environments.

Excellent Surface Quality The glass-ceramic can be polished to a high degree of finish, making it suitable for optical components where surface quality is paramount. This property ensures minimal light scattering and maximum performance in optical systems.

Chemical Resistance Zerodur is resistant to many chemicals, making it ideal for use in harsh environments. Its durability extends the lifespan of components, reducing maintenance costs and downtime.

Applications of Zerodur Glass-Ceramic

Optical Systems Zerodur is widely used in the manufacture of high-performance mirrors and substrates for telescopes. Its thermal stability ensures that optical alignment is maintained, critical for astrophotography and space observation.

Aerospace Components In the aerospace industry, Zerodur is utilized for various applications, including satellite components and instruments. Its lightweight yet sturdy nature helps in minimizing the overall weight of spacecraft while ensuring structural integrity.

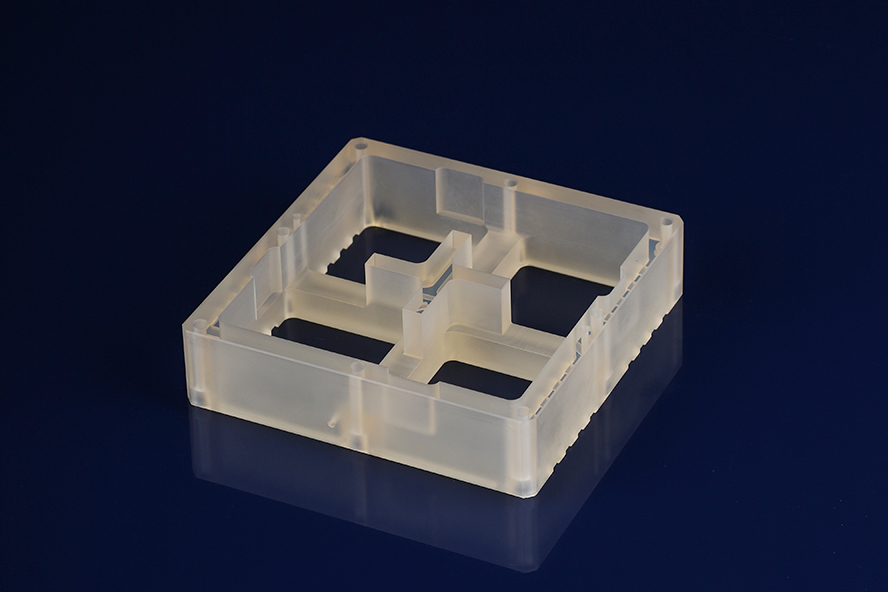

High-Tech Manufacturing Precision machinery and tooling benefit from Zerodur’s properties, allowing for the production of components that require exact dimensions and stability during machining processes.

Research and Development Zerodur is also a preferred material in laboratories and research facilities where precision and reliability are essential. Its ability to maintain form under different conditions makes it invaluable for experimental setups.

Why Choose Zerodur?

When considering materials for precision applications, Zerodur glass-ceramic stands out due to its unmatched combination of properties. Whether for optical devices, aerospace components, or high-tech machinery, Zerodur offers a reliable solution that enhances performance and longevity.

Conclusion

In an era where precision and reliability are non-negotiable, Zerodur glass-ceramic emerges as a leading choice for various high-tech applications. Its thermal stability, low expansion, and exceptional surface quality position it as the ultimate material for industries demanding the highest standards. For manufacturers and engineers, integrating Zerodur into their processes not only enhances product quality but also ensures competitive advantages in the market.

Explore the possibilities of Zerodur glass-ceramic for your next project. Contact our team of experts today to learn how this innovative material can meet your specific needs and drive your applications to new heights.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023