Comprehensive Guide to Aluminum Nitride: Machining, Manufacturers, Costs, and Applications

Introduction

Aluminum nitride (AlN) is a versatile advanced ceramic material known for its exceptional thermal conductivity, electrical insulation, and mechanical strength. As industries increasingly seek high-performance materials, understanding aluminum nitride machining, manufacturers, costs, and its various uses becomes essential.

AlN Ceramic

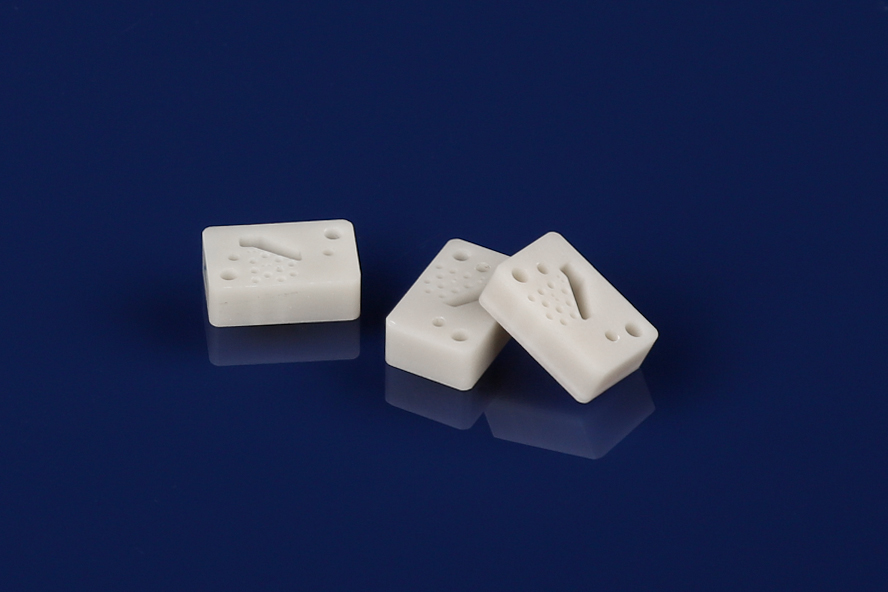

As an advanced ceramic, AlN offers unique benefits over traditional materials. Its low thermal expansion coefficient and high thermal conductivity make it suitable for applications in the semiconductor industry, automotive, and aerospace sectors. AlN ceramics can also be engineered for specific needs, including custom shapes and sizes to meet diverse industry requirements.

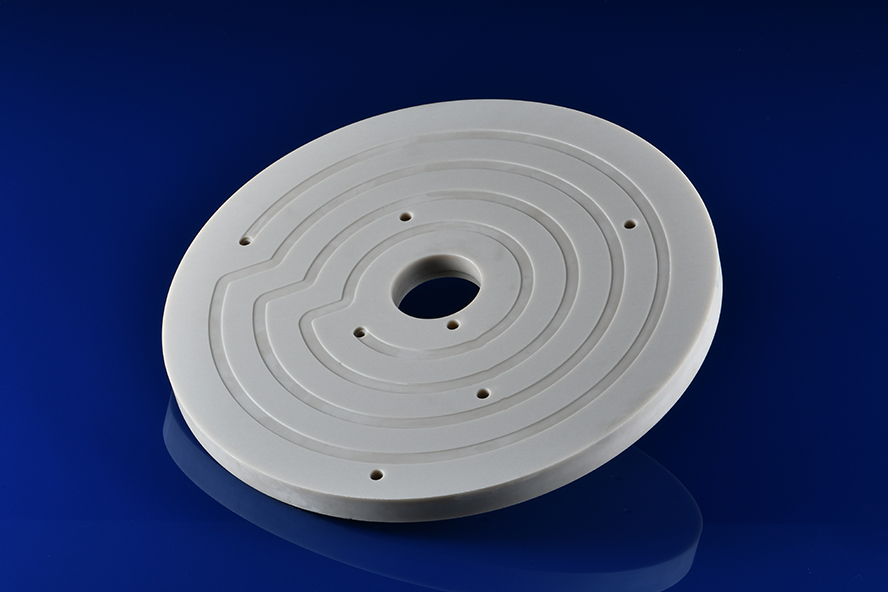

Aluminum Nitride Machining

Machining aluminum nitride presents unique challenges and opportunities. Due to its hardness and brittleness, specialized techniques and tools are required for effective machining. Techniques such as diamond grinding and high-speed machining are often employed to achieve the desired shapes and dimensions. It’s crucial to use appropriate coolant to minimize thermal stress and prevent damage during the process.

Aluminum Nitride Manufacturers

Jundro Ceramics is a professional manufacturer of Aluminum nitride ceramics that can meet the high-performance technical ceramic needs of your industry. We have rich experience in material design, processing, and application. If you need customized (AlN), please contact us

Aluminum Nitride Cost

The cost of aluminum nitride can vary significantly based on several factors, including purity, form (e.g., powders, substrates, or custom parts), and manufacturing processes. While aluminum nitride generally has a higher upfront cost compared to other ceramics, its superior properties often lead to cost savings in applications requiring high thermal conductivity and electrical insulation. Understanding the long-term benefits can help justify the initial investment.

Aluminum Nitride Uses

Aluminum nitride finds applications in various fields, including:

Electronics: Used as substrates for power devices and LED packaging due to its excellent thermal conductivity.

Aerospace: Utilized in components that require lightweight and high-strength materials.

Automotive: Employed in sensors and electronic control units where thermal management is critical.

Biomedical: Investigated for use in biocompatible devices due to its non-toxic nature.

Conclusion

Aluminum nitride is a critical material in modern engineering, offering unique properties that enhance performance across a wide range of applications. Understanding the machining processes, manufacturer options, cost considerations, and diverse uses of AlN is essential for making informed decisions in material selection. As technology continues to advance, aluminum nitride's role in various industries is poised to expand, making it a material worth considering for your next project.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023