Aluminum Nitride Ceramics in Semiconductors

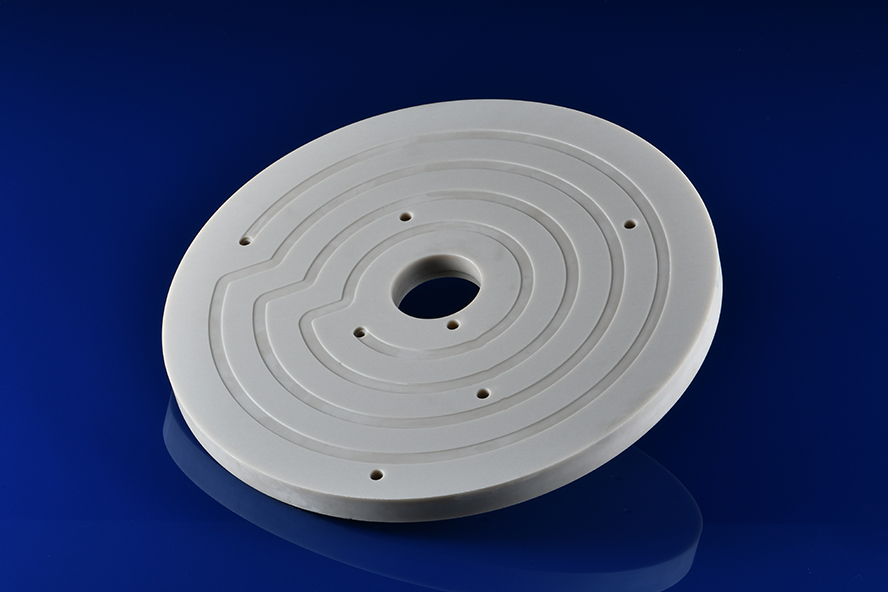

AlN ceramics have quickly become one of the go-to materials in semiconductor production due to their combination of thermal, electrical and mechanical properties that meet industry requirements for semiconductor production. Their outstanding combination of thermal conductivity, low dielectric constant and excellent electrical insulation properties make AlN an attractive material choice in various semiconductor applications - with this article exploring some key applications where AlN can fill these needs within this evolving sector.

Aluminum Nitride Ceramics for Thermal Management in Power Electronics

One of the main applications of AlN ceramics lies in thermal management for power electronics devices such as high-power transistors. Modern semiconductor devices create significant heat while operating, so having efficient heat dissipation properties of AlN allows these semiconductor devices to remain running and perform optimally over time.

Heat Spreaders: AlN ceramics can be utilized in heat spreaders to evenly dissipate heat away from critical components, while AlN-based substrates are utilized in high power devices for increasing thermal conductivity, thus decreasing risks of overheating while simultaneously permitting higher power densities.

Aluminum Nitride Ceramic Insulating Substrates in Integrated Circuits Aluminum nitride ceramics provide excellent electrical insulating properties with their low dielectric constant and high resistivity values, making them the ideal insulating substrates in integrated circuits to prevent electrical interference between components during high frequency/power applications. These substrates must provide effective isolation properties to be effective insulators substrates in integrated circuits.

Multilayer Substrates: AlN substrates provide essential support in creating multilayer semiconductor packages, which combine several semiconductor dies into compact spaces while offering maximum electrical insulation.

AlN ceramics have long been employed in radio frequency (RF) devices due to their low dielectric loss, helping enhance signal transmission while simultaneously improving overall device efficiency.

High-Frequency and High-Voltage Applications

With the advent of high frequency/voltage applications like 5G telecom and electric vehicle power electronics, semiconductor manufacturing technology is pushing its performance envelope further than ever. Aluminum nitride ceramics play an essential part here due to their ability to withstand intense operating environments without losing performance over time.

5G Telecom: As demand for higher frequencies and faster communication speeds increases, AlN ceramics have found increased use as 5G radio-frequency filters and transceivers to ensure signal clarity while decreasing power losses.

Electric Vehicles (EVs): AlN ceramics play an integral part in electric vehicle power inverters and converters, which require materials capable of managing high voltage while remaining thermally stable.

LED and Laser Diode Applications

Aluminum nitride ceramics play an indispensable role in LED (light-emitting diode) and laser diode applications, where precise thermal control and electrical insulation is essential to performance and lifespan. AlN ceramics not only improve thermal management of these devices but also aid the creation of smaller yet higher output solutions.

LED Heat Sinks: AlN heat sinks are commonly found in LED assemblies to improve heat dissipation, thus prolonging their lives by preventing overheating.

Laser Diode Packages: When packaging high-powered laser diodes, AlN substrates and packages are often utilized to efficiently manage thermal loads while offering electrical insulation; this helps ensure optimal device operation without overheating that could compromise internal components.

Packaging and Encapsulation

The semiconductor packaging industry is constantly innovating due to a surge in consumer demand for smaller, more efficient devices that provide increased functionality. Aluminum nitride ceramics have increasingly become the go-to material for packaging semiconductor devices due to their excellent thermal, mechanical, insulating, and mechanical properties.

Hermetic Packages: AlN ceramics make excellent hermetic containers to safeguard sensitive semiconductor components against moisture intrusion, contamination and thermal stress - improving reliability overall.

Encapsulation: When placed in harsh environments where temperatures and mechanical strain are prevalent, AlN encapsulation protects semiconductor devices by guaranteeing their durability and stable operation.

At Jundro Ceramics, we adhere to a rigorous quality management system and utilize state-of-the-art equipment for processing and testing finished products. This ensures that every aluminum nitride (AIN) product meets our customers' needs and upholds high standards. Additionally, our customer service team offers comprehensive technical support, including assistance with product selection, processing technology consultation, and after-sales service. Our goal is to provide timely and professional solutions for all our customers. Contact us to learn more about aluminum nitride ceramic materials. Detailed information and application cases for these materials will help your project thrive and succeed.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023