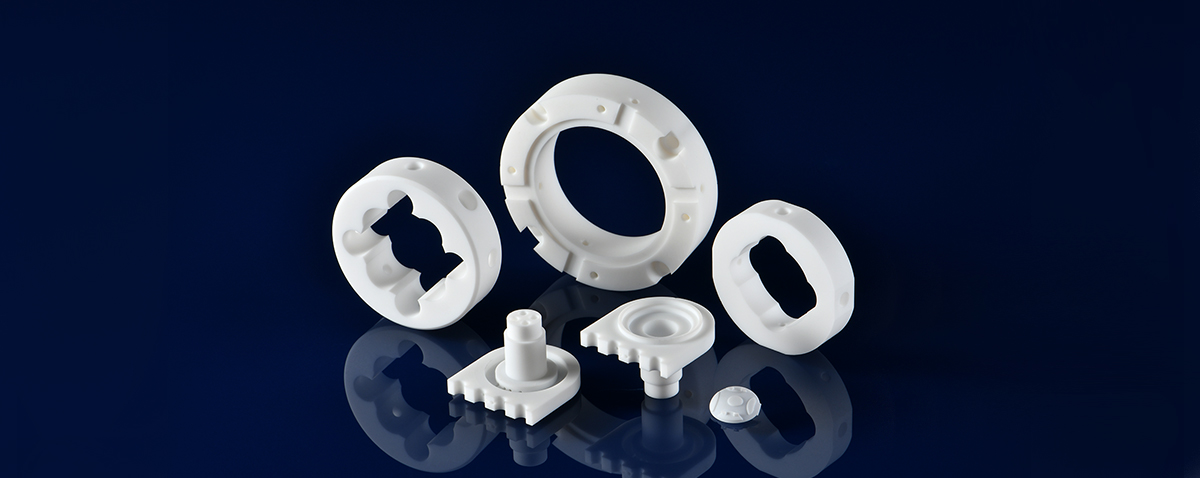

Macor

When it comes to high-end ceramics, Macor is the most popular in the industry. This unique machinable glass ceramic combines excellent mechanical, thermal, and electrical properties, making it an ideal solution for engineering that requires high precision, high reliability, and ease of manufacturing.

What is Macor?

Macor is a glass mica ceramic developed by Corning Inc. Unlike traditional ceramics that are usually difficult to process, Macor can be easily machined with standard tools without the need for diamond cutting. This ability to process complex shapes and designs without the need for extensive post-processing saves time and costs.

Main features of Macor

Macor has multiple advantageous features that make it a valuable material for various industries:

High operating temperature: Macor can operate continuously at temperatures up to 800 ° C, with a peak operating temperature of 1000 ° C. It remains stable in extreme hot environments.

Excellent electrical insulation: Macor has high dielectric strength (40 kV/mm), suitable for insulation components in high-voltage environments.

Low thermal conductivity: Macor has low thermal conductivity (1.46 W/m · K), making it an effective insulation material to prevent unnecessary heat transfer in sensitive applications.

Dimensional stability: Even when exposed to high temperatures, Macor exhibits low thermal expansion (9.3 x 10 ^ -6/° C), ensuring dimensional tolerances are maintained throughout the entire temperature range.

Chemical resistance: Macor does not react with many chemicals, making it suitable for corrosive environments.

Macor's Applications

Due to its versatility, Macor has been applied in a wide range of industries:

Aerospace and Defense

The aerospace industry relies on materials that can withstand extreme environments. The high temperature resistance and thermal stability of Macor make it an ideal choice for insulation components in engines, sensors, and other sensitive aerospace equipment.

medical apparatus and instruments

In the medical field, Macor's biocompatibility and ability to maintain sterilization standards are key. It is used for diagnostic equipment, surgical tools, and other medical devices that require precision machining and heat resistance during disinfection processes.

Semiconductors and Electronics

Macor's excellent electrical insulation and low thermal expansion make it suitable for the electronics and semiconductor industries, where it can be used as a material for substrates, insulators, and test fixtures.

Vacuum environment

Macor is often used in high vacuum applications due to its low air release performance. It is an ideal choice for vacuum chamber components, insulators, and connectors in research laboratories and space equipment.

Why choose Macor?

Macor combines the processability of plastics with the thermal and mechanical properties of ceramics. This balance makes it a favorite among engineers and manufacturers who require precise, durable, and heat-resistant parts.

The advantages of Macor:

Easy to process: No special tools required, making the material easier to quickly shape and customize solutions.

No post firing: After processing, Macor does not require additional firing, further simplifying the manufacturing process.

Cost effectiveness: Complex parts can be processed without expensive diamond tools or additional processing steps, thereby reducing production costs.

Optimize Macor for your project

It is crucial to collaborate with experienced manufacturers who understand material properties in order to fully utilize Macor. Appropriate cutting speed, tool selection, and machining techniques are crucial for achieving optimal results.

Macor manufacturer

Jundro Ceramics excels in providing high-quality Macor ® Materials and processing services meet a wide range of precision machining needs, whether it is design and development or mass production. Our comprehensive service scope includes material selection, precision machining, surface treatment, and quality inspection to ensure that each product can perform at its best in practical applications.

conclusion

Macor can process glass ceramics with unparalleled processability, high temperature performance, electrical insulation, and thermal stability. Its versatility, reliability, and cost-effectiveness make it the preferred choice for industries ranging from aerospace to medical equipment. By utilizing Macor, you can benefit from advanced ceramic properties while simplifying the manufacturing process, accelerating engineering, and reducing costs.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023