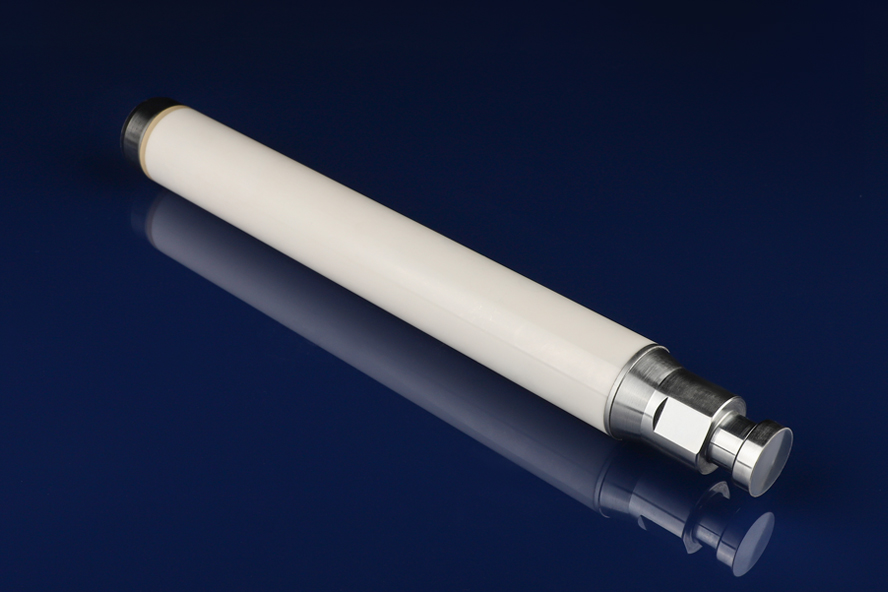

Ceramic Plungers Are The Future Of High Performance Pumping Solutions

Ceramic plungers have long been recognized for their long-term reliability in industrial pumping applications. Fabricated from advanced ceramic materials, ceramic plungers are constructed to withstand extreme conditions while continuing to deliver reliable performance. In this article we look at their benefits and uses across industries.

Ceramic plungers feature outstanding wear resistance, offering extended service lives compared with conventional materials and decreasing replacement and maintenance needs. This reduces maintenance expenses significantly over time.

Corrosion Resistance: Plungers made of advanced ceramic materials are highly resistant to chemical corrosion, making them suitable for use in harsh environments.

Thermal Stability: Ceramic plungers maintain their performance and structural integrity at higher temperatures, guaranteeing reliable operation under extreme conditions.

Smooth Operation: Their smooth surfaces reduce friction to enhance pumping systems' efficiency and effectiveness.

Applications of Ceramic Plungers

Chemical Processing: Ceramic plungers are widely utilized in chemical processing pumps to safely handle aggressive substances that require reliable long-term performance, providing long-lasting service life and maximum reliability.

Water Treatment: Ceramic plungers used in pumps at water treatment plants help resist wear and corrosion caused by particles and chemicals, providing efficient and continuous operation of pumps.

Food and Beverage Industry: Ceramic plungers are employed in pumps used for processing food and beverages, where they offer durability against wear-induced corrosion due to various substances used during processing operations - helping maintain hygiene while improving efficiency and yields.

Pharmaceutical Industry: Plungers designed specifically for pharmaceutical pumps can handle aggressive chemicals while upholding performance and integrity of pumps, helping keep users running uninterrupted and on schedule.

Conclusion Its Ceramic plungers represent the future of high-performance pumping solutions, boasting superior wear and corrosion resistance, thermal stability and smooth operation. Utilizing ceramic plungers within chemical processing, water treatment, food and beverage and pharmaceutical industries ensures increased efficiency with reduced maintenance costs and extended equipment life compared to their metal counterparts. Jundro Ceramics' Ceramic Plungers processing solutions help provide reliable stability during special scenarios while remaining cost effective and sustainable for optimal performance and sustainability goals.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023