Macor is a high-performance machinable glass ceramic developed by Corning, commonly used as a substitute for other difficult to machine ceramic materials Specifically, Macor can serve as a substitute for the following ceramic materials:

1. Aluminum oxide ceramics (Al ₂ O3): Aluminum oxide ceramics have high hardness and wear resistance, but are difficult to process. Macor is relatively easy to process and can replace alumina ceramics in many applications, especially for parts that require complex geometric shapes or precise dimensions.

2. Aluminum nitride ceramics (AlN): Aluminum nitride ceramics have excellent thermal conductivity, but are also difficult to process. Macor can replace aluminum nitride ceramics in applications that require moderate thermal conductivity but are easier to process.

3. Zirconia ceramics (ZrO ₂): Zirconia ceramics are known for their high strength and wear resistance, but the processing is complex and costly. Macor can replace zirconia ceramics in situations where high precision machining is required but strength requirements are not high.

4. Other high-performance ceramics, such as silicon nitride (Si ∝ N ₄), silicon carbide (SiC), etc., although these materials perform well in high temperatures and extreme environments, their processing difficulty and cost are relatively high. Macor can provide more economical and convenient solutions in some non extreme environmental applications.

The advantages of Macor include:

Easy to process: Conventional metal processing equipment can be used for drilling, milling, turning, and other operations.

Good dimensional stability: Maintain dimensional stability over a wide temperature range.

• Low thermal expansion coefficient: Similar to some metals and other ceramic materials, it helps to match the thermal expansion coefficient of mating components.

Excellent electrical insulation performance: suitable for electronic and electrical applications.

Macor's applications include:

1. Electronic and Electrical Engineering

Insulator: An insulator used for high voltage and high frequency applications.

Connectors and connectors: Due to its excellent electrical insulation performance and thermal stability, Macor is very suitable for making various connectors and connectors.

Microwave components: insulation and structural materials used in microwave technology.

2. Aerospace

Thermal insulation and insulation materials: used for components in aerospace vehicles that require high temperature stability and electrical insulation performance.

Heat shield: used to protect sensitive electronic devices from high temperatures.

Structural components: Manufacturing structural components that require precision machining and high strength.

3. Semiconductor manufacturing

Wafer gripper: Used to secure and transport wafers during wafer processing.

Insulation brackets and fixtures: used in various semiconductor processing equipment that require high temperature and chemical stability.

4. Medical equipment

Radiation protection material: used for radiation protection in X-ray equipment.

Surgical tools and fixtures: Manufacturing surgical tools and fixtures that require high precision and biocompatibility.

5. Analytical instruments

Optical and optoelectronic components: used for manufacturing insulation and structural components in optical equipment.

Sample holder: Used in various analytical instruments, especially for applications that require high temperature stability.

6. Laser technology

Optical Platform and Base: High precision platforms and bases used in lasers and optical systems.

Optical isolator: Used for manufacturing optical isolators that require electrical insulation and thermal stability.

7. Vacuum technology

Vacuum system components: Due to its low gas release rate and good mechanical processing performance, Macor is suitable for components in vacuum environments.

Vacuum fixtures and supports: used for fixtures and supports in various vacuum equipment.

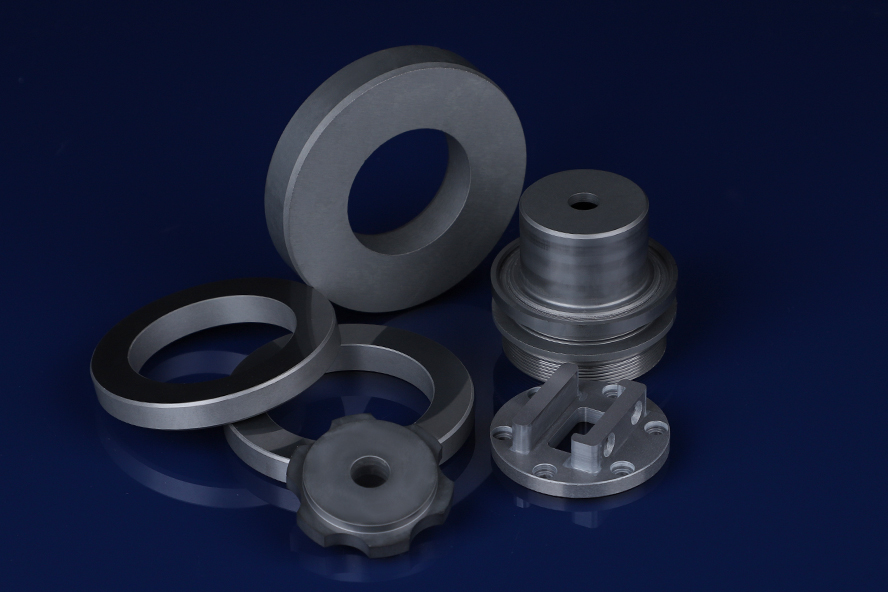

Jundro Ceramics provides you with high-quality processing solutions and products - customized according to your requirements. All Macor ceramics are manufactured by Jundro. This makes it possible to create products that can be used in the most demanding environments.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023