Aluminum oxide ceramics for isolating high-energy particle beams

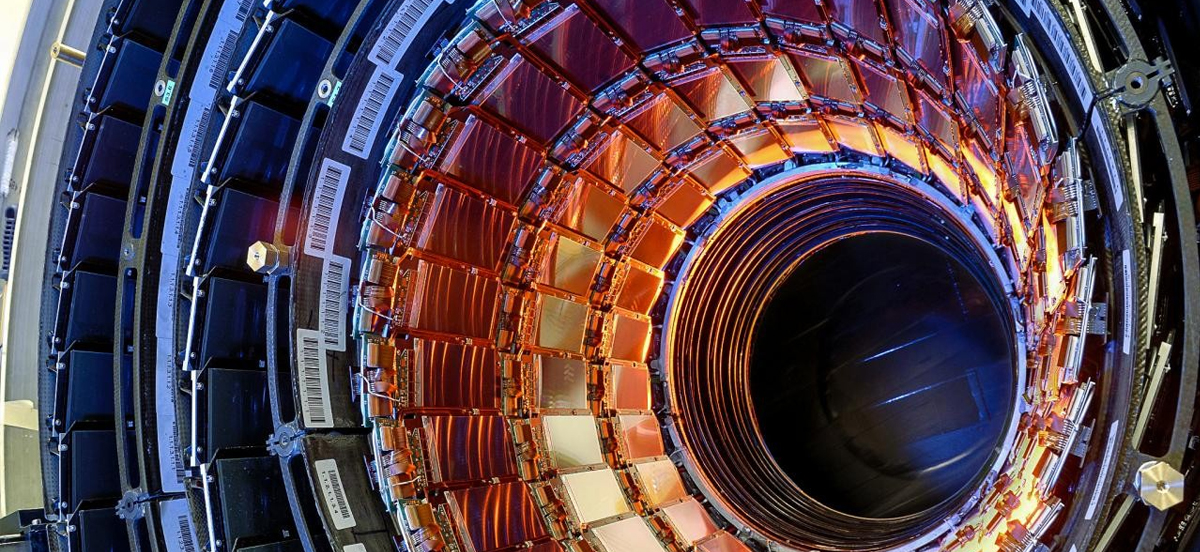

Particle Accelerator is an important scientific tool used to accelerate fundamental particles in the microscopic world in order to study their properties and interactions. These devices are typically composed of strong magnetic and electric fields to cause collisions between particles or with selected targets

Particle accelerators use various specific materials in their design and construction, which must possess specific physical properties and radiation resistance to ensure the stability, performance, and safety of the equipment.

The use of technical ceramics in ultra-high altitude environments to provide electrical insulation without being affected by electromagnetic fields is crucial.

The ceramic materials used in particle accelerators usually have high strength, good electrical insulation performance, and radiation resistance

The role of alumina ceramics in particle accelerators

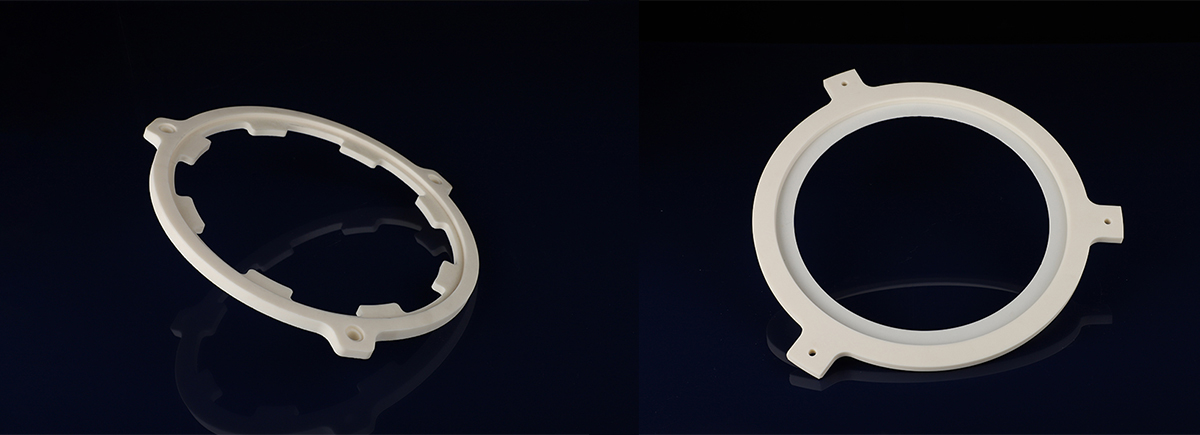

Vacuum chamber window: capable of withstanding the environment of vacuum and high-energy particle beams, maintaining good electrical insulation performance, observing or controlling particle beams in accelerators, such as for beam diagnosis or beam segmentation.

Insulation ring and support components: used as materials for insulation rings and support components in vacuum chambers and accelerator pipelines. They can withstand particle beam irradiation and mechanical pressure while maintaining structural stability and wear resistance

Vacuum sealing element: used to ensure the sealing performance of the vacuum chamber and maintain long-term stability

Aluminum oxide ceramics are a very important material choice in particle accelerators, as they can meet complex environmental requirements, including high vacuum, high-energy particle beam radiation, and stability requirements under high temperature conditions.

Since 2019, Jundro Ceramics has been providing high-precision ceramic material processing services to hundreds of enterprises

Utilize our extensive expertise in technical ceramic manufacturing processes to ensure the production of products that meet your specific application requirements

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023