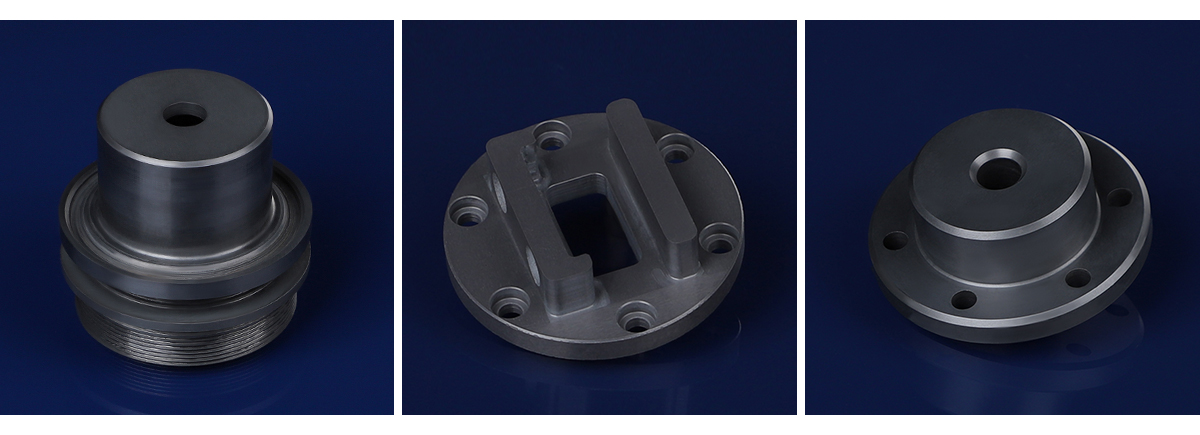

Silicon carbide structural components: a brilliant gem of technology and industry

Silicon carbide (SiC), as a material with excellent mechanical properties and chemical stability, is increasingly becoming a key role in modern technology and industry. It not only performs well in high temperature, high pressure, and corrosive environments, but is also widely used in various fields due to its excellent thermal conductivity and wear resistance. This article will delve into the unique properties, manufacturing processes, and applications of silicon carbide structural components in various industries.

1、 The unique properties of silicon carbide

1.1 Mechanical strength and hardness

The hardness of silicon carbide is close to that of diamond, making it one of the highest among all ceramic materials, which allows it to remain stable in high wear environments. In addition, its compressive strength is extremely high, and it can maintain structural integrity and is not easily deformed under high load conditions.

1.2 Thermal conductivity and thermal stability

Silicon carbide has a very high thermal conductivity, which allows it to effectively dissipate heat in high-temperature environments and maintain the stability of structural components. Its low coefficient of thermal expansion makes it less prone to deformation due to temperature changes, making silicon carbide an ideal material for high-temperature applications.

1.3 Corrosion resistance and chemical stability

Silicon carbide has high resistance to most acidic and alkaline substances, and can maintain its chemical stability even in highly corrosive environments. This characteristic makes it widely used in industries such as chemical and petroleum.

2、 Manufacturing process of silicon carbide structural components

2.1 Hot press sintering

Hot pressing sintering is the most commonly used process in the manufacturing of silicon carbide structural components. By sintering silicon carbide powder under high temperature and pressure, structural components with high density and superior performance can be obtained. This process can effectively reduce the pores in the material, improve its mechanical strength and wear resistance.

2.2 Reaction sintering

Reactive sintering is the process of mixing silicon carbide powder with carbon materials and generating silicon carbide through gas reactions at high temperatures. This process can produce structurally complex components with relatively low production costs. Reaction sintered silicon carbide products usually have good mechanical properties and chemical stability.

2.3 Vapour deposition

Vapor deposition is a high-precision manufacturing process that deposits silicon carbide gas on the surface of the substrate at high temperatures to form a dense silicon carbide coating. This method is commonly used to manufacture high-performance electronic devices and wear-resistant coatings, which can accurately control the coating thickness and composition.

3、 Application fields of silicon carbide structural components

3.1 Aerospace

In the aerospace field, silicon carbide is widely used in high-temperature components such as rocket nozzles and gas turbine blades due to its advantages of high strength, lightweight, and high temperature resistance. These components operate in extreme environments, and the excellent performance of silicon carbide ensures their reliability and lifespan.

3.2 Electronic Industry

The excellent thermal conductivity and high pressure resistance of silicon carbide have made it widely used in the electronic industry, especially in power devices operating under high frequency and high temperature conditions. Silicon carbide semiconductor materials have the characteristics of wide bandgap and high electron mobility, making them ideal materials for producing high-performance electronic devices.

3.3 Energy sector

In the energy field, silicon carbide is used as a substrate for manufacturing nuclear reactor structures and solar cells. Its radiation resistance and high thermal conductivity make it outstanding in these high energy density environments, significantly improving the efficiency and safety of the equipment.

3.4 Chemical and Petroleum Industries

Due to its high corrosion resistance, silicon carbide is used in the chemical and petroleum industries to manufacture equipment such as pumps, valves, and heat exchangers. Even in strong acidic and alkaline environments, silicon carbide structural components can still maintain long-term stable operation.

4、 Future outlook

With the continuous progress of technology, the application prospects of silicon carbide are becoming increasingly broad. The continuous research and development of new manufacturing technologies will further improve the performance of silicon carbide structural components and reduce production costs. In the future, silicon carbide will not only be limited to high-end industrial fields, but will also gradually enter daily life, becoming a shining pearl of modern technology and industry.

In summary, silicon carbide structural components have demonstrated unparalleled advantages in multiple fields due to their unique physical and chemical properties. It is not only an important driving force for technological innovation, but also a cornerstone of industrial development. We have reason to believe that with the continuous deepening of research, silicon carbide will bring more surprises and convenience to humanity.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023