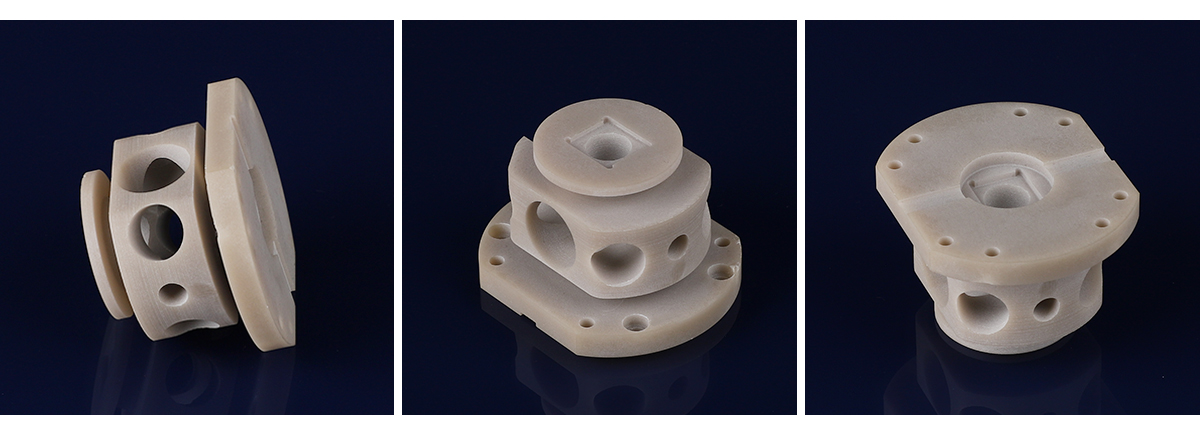

Aluminum nitride ceramic valve cores used in the automotive industry

Driven by advances in materials science and engineering, the automotive industry is constantly developing. Among these innovations, aluminum nitride (AlN) ceramic valve cores are a significant breakthrough. These components have excellent thermal conductivity, mechanical strength, and chemical stability, making them ideal choices for various automotive applications.

The Properties of Aluminum Nitride Ceramics

Thermal conductivity coefficient

One of the most significant characteristics of aluminum nitride ceramics is their high thermal conductivity. The maximum thermal conductivity of AlN can reach 285W/m · K, which is significantly higher than traditional ceramic materials. This characteristic is crucial for automotive applications that require efficient heat dissipation, such as in engine components and electronic systems.

Mechanical strength and hardness

Aluminum nitride ceramics exhibit impressive mechanical strength and hardness. The Vickers hardness of AlN ceramics is about 1100HV, which is durable, wear-resistant, and deformed. This makes them suitable for use in high stress environments, such as valve cores in engines, where they must withstand constant mechanical forces and grinding conditions.

Chemical stability and corrosion resistance

AlN ceramics have chemical stability and corrosion resistance. They will not react with most chemicals, including automotive fluids and gases, ensuring their lifespan and reliability in harsh environments. This chemical stability is particularly beneficial for components exposed to fuel, lubricants, and exhaust gases.

Electrical insulation

Although aluminum nitride ceramics have high thermal conductivity, they are excellent electrical insulators. This unique performance combination makes it very suitable for use in automotive electronic products, where thermal management and electrical insulation are crucial.

Application in the automotive industry

Aluminum nitride ceramic valve cores are changing various aspects of automotive design and performance. Their unique characteristics enable them to be used in various critical applications, improving engine efficiency, reliability, and overall vehicle performance.

Engine components

In internal combustion engines, valve cores play a crucial role in controlling the flow of air and fuel mixtures into the combustion chamber and exhaust gases. Aluminum nitride ceramic valve core provides excellent thermal management, reduces overheating risk, and improves engine efficiency. Their high mechanical strength and wear resistance ensure long-term durability, even under extreme conditions of high-performance engines.

Electronic systems

Modern vehicles are equipped with many electronic systems that require effective thermal management and electrical insulation. Aluminum nitride ceramics are used in electronic control units (ECU), power modules, and sensors to help dissipate the heat generated by electronic components while providing good electrical insulation. This improves the reliability and lifespan of automotive electronic products, which are crucial for vehicle safety and performance.

exhaust system

Aluminum nitride ceramic valve cores are also used in exhaust systems to help reduce emissions and improve fuel efficiency. Their chemical stability and corrosion resistance make them an ideal choice for resisting harsh exhaust conditions, ensuring consistent performance throughout the vehicle's lifespan.

Hybrid and electric vehicles

The rise of hybrid and electric vehicles has brought new challenges to thermal management and component reliability. AlN ceramics are increasingly being used in battery management systems, inverters, and other high-power electronic components for electric vehicles. Their ability to effectively dissipate heat and provide electrical insulation is crucial for maintaining the performance and safety of these advanced vehicles.

Advantages compared to traditional materials

Compared to traditional materials used in automotive valve cores, such as steel and silicon carbide, aluminum nitride ceramics have several obvious advantages:

1. Excellent thermal management: AlN's high thermal conductivity is superior to most traditional materials, ensuring better heat dissipation and reducing thermal stress on components.

2. Enhanced durability: The mechanical strength and hardness of aluminum nitride ceramics extend the service life of components and do not require frequent replacement.

3. Chemical resistance: The corrosion resistance and chemical reactivity of AlN ceramics ensure consistent performance in the presence of automotive fluids and gases.

4. Electrical insulation: The combination of thermal conductivity and electrical insulation makes AlN ceramics an ideal choice for integrating advanced automotive electronic products.

The aluminum nitride ceramic valve core represents a significant advancement in automotive engineering. Its excellent thermal conductivity, mechanical strength, chemical stability, and electrical insulation performance make it indispensable in various applications of modern automobiles. With the continuous development of the automotive industry, the adoption of AlN ceramics will undoubtedly help to create more efficient, reliable, and environmentally friendly cars. Jundro's technology for processing aluminum nitride ceramics has been continuously growing through continuous innovation and progress, providing high-quality customized services to global customers.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023