Aluminum nitride (AlN) ceramics have been widely recognized in recent years due to their excellent thermal conductivity, electrical insulation, and chemical stability. These unique properties make AlN ceramics a key material in advanced technological applications, especially in the wafer manufacturing industry.

Aluminum nitride ceramics have various properties, making them highly suitable for various high-performance applications. The main features include:

1. High thermal conductivity: AlN ceramics have a thermal conductivity of up to 285 W/mK, making them an ideal choice for thermal management applications that require efficient heat dissipation.

2. Electrical insulation: Although AlN ceramics have high thermal conductivity, they still maintain excellent electrical insulation performance, with a dielectric constant of about 8.5 and a resistivity greater than (10 ^ {12} ) Ω · cm.

3. Mechanical strength and hardness: AlN ceramics are known for their mechanical strength, with a Vickers hardness of approximately 1100 kg/mm ², Suitable for structural components that withstand mechanical stress.

4. Chemical stability: These ceramics are chemically inert in most environments and can resist many acids and bases, which improves their durability and lifespan in various applications.

5. Thermal expansion coefficient: The thermal expansion coefficient of AlN is close to the thermal expansion rate of silicon, reducing thermal stress and making it compatible with silicon-based devices.

The production of aluminum nitride ceramics involves several complex steps, each of which is crucial for achieving the required material properties.

1. Powder synthesis: High purity aluminum nitride powder is synthesized by direct nitridation of aluminum or carbothermal reduction of aluminum oxide. The choice of synthesis method affects the purity and particle size distribution of the final product.

2. Powder processing: The synthesized AlN powder is ground and screened to obtain a uniform particle size. Introduce additives such as adhesives, plasticizers, and dispersants to promote the molding process.

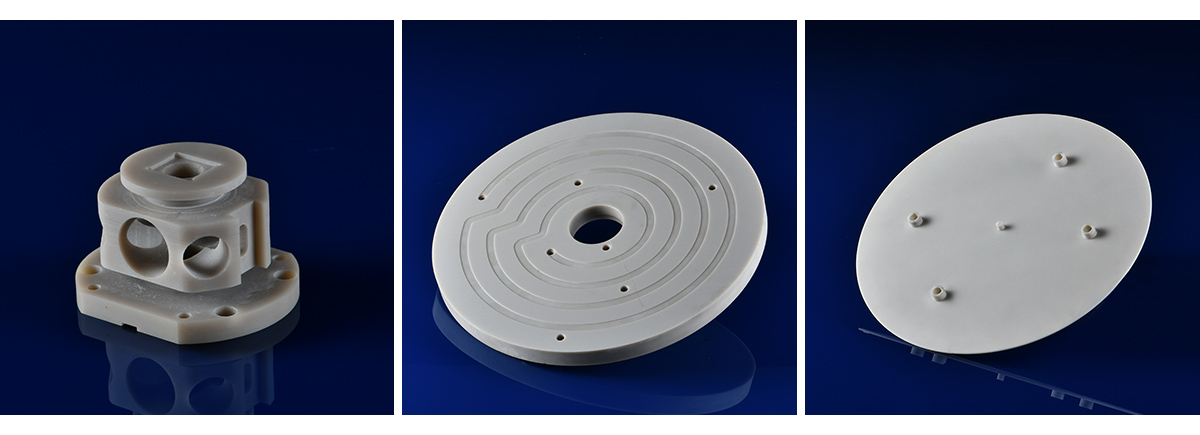

3. Forming: Use techniques such as uniaxial compression, isostatic pressing, or extrusion to shape the processed powder into the desired shape. Injection molding is also suitable for complex geometric shapes.

4. Sintering: The formed body is sintered in a nitrogen atmosphere at high temperature (1700-2000 ° C) to achieve densification. The sintering process is crucial as it directly affects the microstructure of ceramics, thereby affecting their thermal and mechanical properties.

5. Post sintering process: Mechanical processing, grinding, and polishing are carried out to meet strict dimensional tolerances and surface smoothness requirements. Due to the hardness and brittleness of AlN ceramics, these processes are particularly challenging.

The wafer manufacturing industry is the core of semiconductor production, heavily relying on materials that can meet strict performance standards. Aluminum nitride ceramics play a crucial role in the industry due to their excellent performance.

1. Heat dissipation element: AlN ceramics are used as substrates and heat sinks in semiconductor devices. Their high thermal conductivity ensures effective heat dissipation, protects sensitive electronic components from overheating, and thus improves the reliability and performance of the equipment.

2. Wafer carrier and chuck: The accuracy of wafer processing is crucial for semiconductor manufacturing. AlN ceramics have high mechanical strength and thermal stability, and are used as chip carriers and chucks to ensure maximum reduction of thermal expansion and deformation during processing.

3. Dielectric layer: In some semiconductor devices, AlN ceramics are used as dielectric layers due to their excellent electrical insulation performance. This application is particularly relevant in high-frequency and high-power electronic devices.

4. Crystal growth crucible: AlN ceramics are used as crucibles for producing silicon carbide (SiC) and gallium nitride (GaN) crystals for growth. Their chemical stability and high melting point make them suitable for high-temperature processes.

The hardness and brittleness of AlN ceramics make machining and finishing processes difficult and expensive. Grinding and polishing require professional diamond tools, but achieving the required surface finish and dimensional accuracy may still be challenging. Although the thermal expansion coefficient of AlN ceramics is relatively low, they still experience thermal stress during rapid temperature changes. This stress may cause cracking or warping, especially in larger components or components with complex geometric shapes.

Aluminum nitride ceramics are an outstanding material with great potential in the high-tech industry, especially in the field of wafer manufacturing. They have a unique combination of high thermal conductivity, electrical insulation, and mechanical strength, making them indispensable in applications that require efficient thermal management and structural reliability. However, the processing of AlN ceramics presents significant challenges that require continuous research and innovation.

The progress in sintering technology, surface treatment, and composite material development is expected to overcome these challenges and unleash the full potential of aluminum nitride ceramics. As the demand for high-performance electronic devices continues to grow, the importance of AlN ceramics in the semiconductor industry will increase, driving further technological progress and innovation in this important field.

Dongguan Jundro ceramics Technology Co.,Ltd

E-mail:info@jundro.com

Tel:+86-769-82913501

Fax:+86-769-82913801

Add: Room 306, Gate B, Unit 1, Block 2 South, No. 1 Yile Road, Songshan Lake, Dongguan City, Guangdong Province, China(523808)

© August Dongguan Jundro ceramics Technology Co.,Ltd- 2023